Metal Sheet Fabrication: A Key Process in Modern Manufacturing

Metal sheet fabrication is an essential process in the world of modern manufacturing. From the construction of everyday appliances to intricate machinery, this process plays a critical role in producing quality, durable, and functional products. Metal sheets are used in various industries, including automotive, construction, electronics, aerospace, and many others. This article will explore the different aspects of metal sheet fabrication, its significance in manufacturing, common techniques used, and its application across various industries.

What Is Metal Sheet Fabrication?

Metal sheet fabrication refers to the process of transforming metal sheets into usable parts or structures. This process involves cutting, bending, welding, and assembling metal sheets to form specific shapes and designs. It is commonly used for creating products like car bodies, building panels, electrical housings, kitchen appliances, and more.

The metal sheets used in fabrication come in different thicknesses, ranging from thin sheets for lightweight applications to thicker sheets for structural purposes. The choice of metal material depends on the product’s requirements, such as strength, corrosion resistance, weight, and conductivity.

Common Metal Materials Used in Sheet Fabrication

Several materials are used for metal sheet fabrication, each with unique properties that make them suitable for different applications. Here are some of the most commonly used metals in sheet fabrication:

- Steel: One of the most widely used materials, steel is valued for its strength, durability, and versatility. It is often used in construction, automotive manufacturing, and heavy-duty machinery. Stainless steel, a corrosion-resistant variation of steel, is particularly popular for kitchen appliances, medical equipment, and architectural structures.

- Aluminum: Aluminum is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. These properties make aluminum ideal for industries such as aerospace, automotive, and electronics. Aluminum sheet fabrication is widely used for producing parts like car bodies, aircraft components, and heat exchangers.

- Copper: Known for its excellent electrical conductivity and corrosion resistance, copper is often used in electronics and electrical components. Copper sheets are commonly fabricated into products such as electrical wiring, circuit boards, and heat exchangers.

- Brass and Bronze: These alloys of copper are often used in sheet fabrication due to their attractive appearance, corrosion resistance, and durability. They are commonly used in decorative applications, plumbing fittings, and musical instruments.

- Titanium: Titanium is known for its exceptional strength-to-weight ratio and resistance to corrosion, making it ideal for aerospace, medical, and marine industries. Titanium sheet fabrication is used for manufacturing high-performance components like aircraft parts, implants, and marine structures.

Key Techniques in Metal Sheet Fabrication

Metal sheet fabrication involves several key techniques that allow manufacturers to create intricate and durable components. The most commonly used techniques include:

1. Cutting

Cutting is the process of separating a metal sheet into smaller pieces or specific shapes. There are various methods of cutting metal, depending on the thickness and material of the sheet:

- Laser Cutting: Laser cutting uses a high-powered laser to cut through metal with extreme precision. It is ideal for creating complex shapes and intricate designs.

- Plasma Cutting: Plasma cutting uses an electrically conductive gas to cut through metal. It is commonly used for cutting thicker sheets of metal and can achieve high cutting speeds.

- Shearing: This process involves cutting metal by applying a high-pressure force. It is typically used for cutting straight lines in thin sheets of metal.

- Water Jet Cutting: In this technique, a high-pressure stream of water mixed with abrasive particles is used to cut metal. It is ideal for cutting thick or heat-sensitive metals without causing deformation.

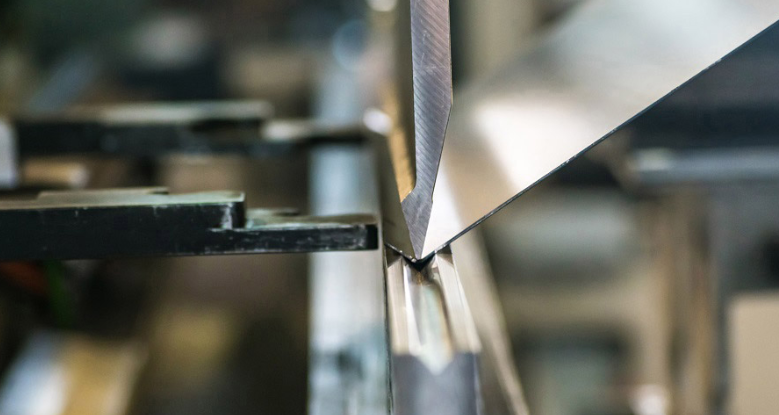

2. Bending

Bending is the process of shaping a metal sheet into a desired angle or curve. The metal is placed between a punch and die, and pressure is applied to bend the sheet. There are several bending techniques:

- V-bending: This is the most common bending process, where the sheet is bent at a specific angle using a V-shaped die.

- Roll Bending: This method is used for creating curved shapes, such as cylindrical or conical parts. The sheet is passed through a set of rollers that apply pressure to form the shape.

- Air Bending: In this process, the sheet is bent using an air cushion or a press brake without the need for a die.

3. Welding

Welding is a crucial process in metal sheet fabrication, used to join different metal pieces together. There are several welding methods, including:

- TIG Welding (Tungsten Inert Gas Welding): TIG welding is known for producing clean and precise welds. It is commonly used for welding thin sheets of metal, especially stainless steel and aluminum.

- MIG Welding (Metal Inert Gas Welding): MIG welding is a versatile and fast welding method, ideal for joining thicker sheets of metal.

- Spot Welding: Spot welding is commonly used for welding sheet metal parts, particularly in the automotive industry. It involves applying pressure and heat to specific points of the metal to create a weld.

4. Assembly

After the metal sheets are cut, bent, and welded into the desired shapes, the components are assembled into final products. Assembly can involve additional processes like fastening, riveting, or using adhesives to join parts together. This stage requires precision to ensure the product’s functionality and durability.

Applications of Metal Sheet Fabrication

Metal sheet fabrication is used in a wide range of industries. Below are a few key sectors that rely heavily on this process:

1. Automotive Industry

Metal sheet fabrication is crucial in the automotive sector, where it is used to manufacture body panels, frames, exhaust systems, and engine parts. The use of high-strength steel and aluminum in car manufacturing allows for lightweight yet durable vehicles. Advanced techniques like laser cutting and robotic welding are commonly used to produce precise and high-quality automotive components.

2. Aerospace Industry

In the aerospace sector, metal sheet fabrication is used to produce aircraft components, including fuselages, wings, and tail sections. The use of lightweight materials such as aluminum and titanium ensures that aircraft are fuel-efficient while maintaining structural integrity.

3. Construction Industry

The construction industry also benefits from metal sheet fabrication, with metal sheets being used for roofing, cladding, frames, and structural elements. Steel fabrication is especially popular for creating buildings, bridges, and other infrastructure due to its strength and durability.

4. Electronics and Electrical Industry

Electronics and electrical products often require metal enclosures, connectors, and heat sinks, which are all produced using metal sheet fabrication. Copper, aluminum, and stainless steel are commonly used to create components that must meet strict electrical and thermal conductivity standards.

Conclusion

Metal sheet fabrication is a vital process in manufacturing that enables the production of a wide range of products used across numerous industries. With advancements in technology and fabrication techniques, manufacturers can create increasingly complex and precise parts that meet the growing demands of modern engineering. Whether it’s for automotive, aerospace, electronics, or construction, metal sheet fabrication will continue to play a key role in shaping the products we use every day.

By understanding the different materials, techniques, and applications involved in metal sheet fabrication, businesses can make informed decisions that improve the quality and efficiency of their manufacturing processes. The importance of this process in shaping our world cannot be overstated.

Post Comment