What is a Gantry Machining Center? Key Features and Benefits

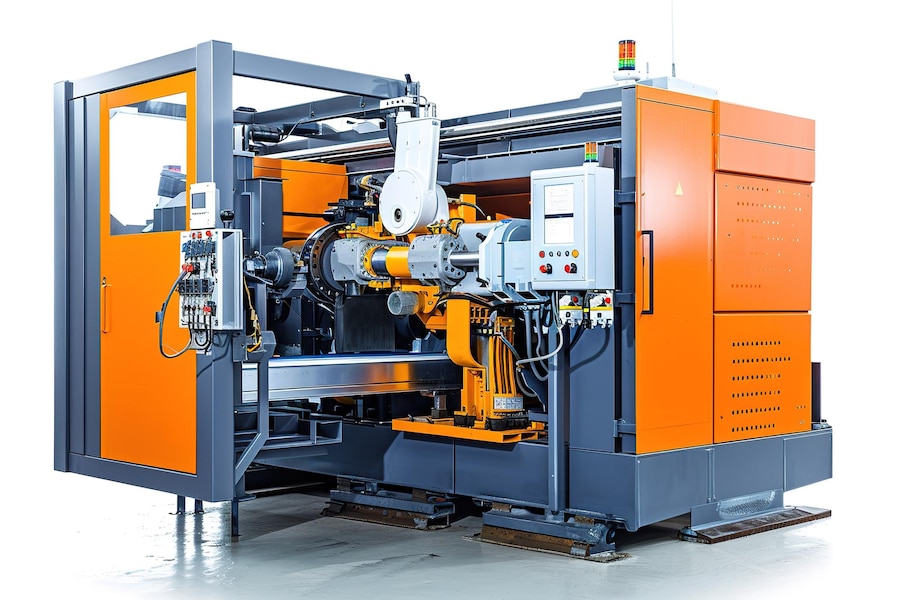

A gantry machining center is a highly specialized CNC (Computer Numerical Control) machine designed to handle large, complex workpieces that require precision, speed, and flexibility. These machines are commonly used in industries such as aerospace, automotive, shipbuilding, and large-scale industrial manufacturing where machining large parts with accuracy is critical.

In this blog, we’ll explore what a gantry machining center is, its key features, and how it benefits industries that rely on large-scale precision manufacturing.

What is a Gantry Machining Center?

A gantry machining center gets its name from the “gantry” structure that supports its machine head and cutting tool. In this setup, the tool moves along a horizontal beam, or gantry, while the workpiece remains stationary or moves on the table. The machine’s frame usually forms a bridge over the workpiece, which allows the machining of very large parts from different angles.

This type of machine is well-suited for heavy-duty operations that involve massive workpieces, such as the production of aircraft parts, automotive molds, and even components for energy industries. The machine can handle everything from drilling and milling to contouring, making it versatile for a variety of applications.

Key Features of a Gantry Machining Center

- Large Work Envelope One of the most significant advantages of a gantry machining center is its large work envelope. The gantry design allows the machine to process oversized workpieces that would be impossible or impractical for traditional machining centers. The wide, open structure of the machine provides enough room to move large parts, making it ideal for industries where size matters.

- High Rigidity and Stability Gantry machining centers are built to be extremely rigid and stable, which is essential when machining large parts that require high precision. The heavy-duty structure and solid foundation minimize vibrations and movement during operation, resulting in more accurate cuts and finishes. This stability is crucial for maintaining dimensional accuracy, especially in aerospace and automotive industries.

- Multi-Axis Machining Many gantry machining centers are equipped with multi-axis capabilities, such as 3-axis, 4-axis, or 5-axis machining. These additional axes allow the cutting tool to approach the workpiece from different angles, providing greater flexibility and reducing the need for multiple setups. Multi-axis machining is especially useful for parts with complex geometries or features that require machining from various orientations.

- High Precision and Accuracy Precision is a critical feature of gantry machining centers. Their design allows them to maintain tight tolerances even when working on large, heavy parts. Many models come with advanced control systems and feedback loops that ensure the tool remains accurate throughout the entire machining process. This level of precision is vital for industries like aerospace, where even minor inaccuracies can compromise safety and performance.

- Customizable Configurations Gantry machining centers are highly configurable, allowing manufacturers to customize the machine according to their specific needs. Whether it’s adding additional spindles, tool changers, or specialized fixtures, these machines can be tailored to optimize production for specific tasks. This flexibility allows companies to get the most out of their investment by adjusting the machine to their unique requirements.

- Automatic Tool Changers (ATC) Most modern gantry machining centers come with automatic tool changers (ATC), which increase efficiency by allowing the machine to automatically switch between different tools during a machining cycle. This capability reduces downtime and enhances productivity, particularly in operations that require multiple machining tasks such as drilling, milling, and boring.

Benefits of Using a Gantry Machining Center

- Increased Efficiency Gantry machining centers are designed for high-efficiency production. Their ability to handle large, complex workpieces in a single setup reduces the need for multiple machines and manual handling. This increased efficiency translates into faster production times and lower operational costs.

- Versatility With their multi-axis capabilities and customizable configurations, gantry machining centers can handle a wide range of tasks. From milling and drilling to contouring and even 3D machining, these machines can be used across different industries for various applications. This versatility makes them an excellent long-term investment for manufacturers.

- Cost-Effective for Large-Scale Projects While the initial investment in a gantry machining center may be high, the machine’s ability to perform multiple operations in one setup makes it cost-effective for large-scale projects. By reducing the need for multiple machines and setups, gantry centers can lower production costs and improve ROI, particularly for companies that work with large, intricate parts.

- Enhanced Precision and Accuracy The high rigidity, stability, and precision of gantry machining centers make them ideal for industries where accuracy is non-negotiable. Aerospace, defense, and automotive industries often require parts with extremely tight tolerances, and gantry centers are up to the task. Their ability to maintain accuracy over large workpieces ensures high-quality results.

- Reduction in Manual Labor Because gantry machining centers can handle large workpieces and perform multiple operations in a single setup, there is less need for manual intervention. This automation reduces the risk of human error, improves safety, and allows manufacturers to focus on other critical tasks, such as quality control and production optimization.

- Improved Workflow With automatic tool changers, multi-axis capabilities, and large work envelopes, gantry machining centers streamline the workflow. Fewer setups mean fewer interruptions, leading to smoother operations and more efficient use of labor and machine time. This makes them ideal for large production runs or projects that demand precision with minimal downtime.

Conclusion

A gantry machining center is an invaluable tool for industries that require high-precision machining of large, complex workpieces. Its key features—such as a large work envelope, high rigidity, multi-axis capabilities, and customizable configurations—make it versatile and efficient for a wide range of applications. The benefits of using a gantry machining center include increased efficiency, enhanced precision, cost-effectiveness, and improved workflow.

Post Comment