What Causes Unexpected Equipment Failures? How Can Manufacturers Reduce Them?

Machines play a crucial role in manufacturing units of industries. You rely on them for production and to fulfill customer demands. Sometimes, they break down without any warning. This can cost time and money and even cause injuries.

Opting for preventive maintenance in manufacturing industry can help avoid these issues. However, you can do so only when you know why unexpected failures happen. This will help you stop future problems, mitigating the risks of unexpected downtimes.

In this article, we will go through the major causes of unexpected equipment failure and what you can do about them.

Reasons Behind Unexpected Equipment Failure

Poor Maintenance

Just like anything else, machines also need regular care. When machines are not cleaned, checked, or fixed on time, small problems grow bigger. Dust, rust, and old parts can slow them down or even make them stop working. Sometimes, workers forget or skip regular checkups to save time or money.

Overuse or Overloading

Every machine is built to do a certain job. If it is used a lot, it gets tired. Overloading a washing machine, running a motor too long, or using a small tool for a big job can break the equipment. Overusing can cause the inside parts to heat up or break. Therefore, it is always better to follow the user guide and give machines time to rest when needed.

Lack of Training

Sometimes, the people using the machines don’t know how to use them properly. This is often because they were not trained well or didn’t read the manual. Even pressing the wrong button or skipping one step can lead to equipment failure. Using the wrong settings can also damage the machine. A small mistake can cause a big problem.

Bad Quality Parts

Machines are made of many small parts. If even one part is weak or made from cheap material, it can affect the whole machine. You may try to save money by using low-cost parts. However, this often leads to more repairs later. Cheap parts wear out quickly, break easily, and may not fit well. Saving a little money now can cost a lot more in the future.

Electrical Issues

Machines are usually powered by electricity. However, if the power goes out or changes quickly, it can damage the machine. Low-grade wires or poor fixtures can also lead to various problems. A power surge can burn circuits. Similarly, loose wires can cause short circuits or sparks. These problems are hard to see but can cause big damage. Using the wrong power source or not grounding equipment properly also increases risk.

Environmental Conditions

Machines don’t like places that are too hot, cold, or wet. Extreme conditions can cause parts to rust, break, or stop working. For example, water can get into electrical parts and cause a short circuit. Meanwhile, heat can melt wires or overheat engines. Similarly, dust can block airflow and jam moving parts.

Software or Control System Failures

Modern machines often use computers or software to work. If the software crashes or has bugs, the machine may stop working. Sometimes, outdated systems fail to integrate with new tools, which leads to several problems. These issues are common, but you often fail to notice them early.

Poor Installation

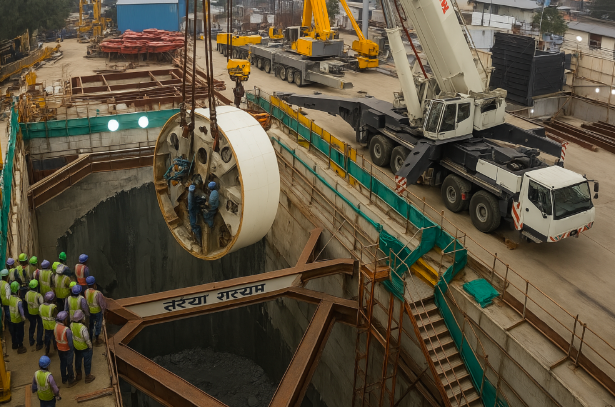

If a machine is not set up correctly at the start, it may fail unexpectedly. This often happens when it wasn’t placed on a level surface, or the parts were not tightened well. Poor setup can cause shaking, leaks, or even fires. It’s always best to let trained professionals install equipment.

Effective Strategies to Reduce Them

The following are some of the most effective ways to reduce these issues.

Regular Maintenance: The first thing you need to do is pay attention to the regular maintenance of machines. Make sure you clean them regularly and address minor problems early to avoid major issues. You should also opt for CMMS implementation services to track and streamline the maintenance process.

Proper Lubrication: Using the right lubricant reduces friction and overheating. This enables different equipment to move freely. As a result, machines remain functional for an extended duration.

Professional Installation: You can experience a machinery failure due to poor installation. Therefore, you should call professionals to install and start the machines for the first time. They will install them at a suitable place to reduce the risk of failures.

Train Your Staff: You should invest in the training of your staff to mitigate the risk of failures. You should schedule regular training sessions to ensure they know how to handle all the equipment. You can offer incentives to encourage them to learn more about the different machines used in your manufacturing unit.

As a business owner, you must know the actual reasons behind unexpected machinery failure. Understanding them and practicing the aforementioned approaches will help you extend the lifespan of your machines and reduce the risk of unexpected failures.