Understanding the Role of Rock Bolts in Underground Construction

Underground construction presents unique challenges that require innovative solutions to ensure structural stability and safety. Among the most essential components in these projects are rock bolts. These anchoring systems play a vital role in reinforcing rock masses, preventing collapses, and enabling safe excavation.

In this blog, we explore the significance of rock bolts, their applications, and the benefits they offer in underground construction.

What Are Rock Bolts?

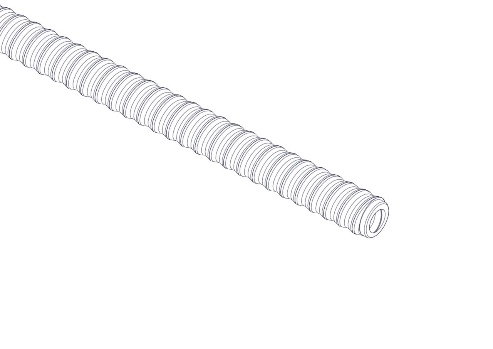

To provide structural reinforcement, drilled holes in rock formations receive the insertion of long, steel rods or bars known as rock bolts. Once installed, these bolts secure unstable rock masses by creating a support system that distributes the load across the surface. This prevents rockfall and enhances the stability of underground structures.

Rock bolts are available in a variety of types.

- Mechanical bolts are expanded at the ends to anchor into the rock.

- Resin Bolts: Secured using resin or grout for enhanced durability.

- Friction Bolts: Rely on friction between the bolt and the rock surface for support.

Specific project requirements and geological conditions determine the choice of each type.

The importance of rock bolts in underground construction.

Environments where excavation or natural geological factors compromise rock stability often host underground construction projects like tunnels, mines, and caverns. Rock bolts serve as a proactive measure to prevent hazardous conditions and structural failures.

1. Safety

The primary role of rock bolts is to enhance safety. By anchoring loose or unstable rock formations, they reduce the risk of rockfall and ensure that excavation sites remain secure for workers and equipment.

2. Cost-Effectiveness

Rock bolts are an economical alternative to more extensive support systems like concrete linings or steel frames. Their installation is faster and requires fewer resources, making them a practical choice for large-scale projects.

3. Versatility

Different geological conditions and project requirements can adapt these bolts. Whether in dense rock formations or soft soil environments, rock bolts provide reliable reinforcement.

4. Longevity

When installed correctly, rock bolts offer long-term stability, reducing the need for frequent maintenance or additional reinforcements.

Applications of Rock Bolts

The versatility of rock bolts makes them indispensable in various underground construction applications:

1. Tunneling

Tunneling projects extensively use rock bolts to stabilize the surrounding rock and prevent collapses. They ensure that tunnels remain safe during and after excavation.

2. Mining

In mining operations, rock bolts are critical for securing mine shafts, adits, and stopes. They help create a safe working environment while enabling deeper excavation.

3. Slope Stabilization

In addition to underground projects, rock bolt are also used to reinforce slopes and embankments, preventing landslides and erosion in open-pit mines and highways.

4. Geotechnical Projects

From subway systems to underground storage facilities, rock bolts are a fundamental component in ensuring the stability of large-scale geotechnical constructions.

How Rock Bolts Work

The effectiveness of rock bolt lies in their ability to create a unified support system within the rock mass. When installed, these bolts apply tension to the rock, which compresses and binds the unstable sections. This tension redistributes stress within the rock, minimizing the chances of displacement or collapse.

The installation process typically involves:

- Drilling Holes: We drill holes into the rock surface to achieve the desired depth and diameter.

- Bolt Insertion: Insert the selected rock bolt type into the drilled hole.

- Securing the Bolt: We anchor the bolt using mechanical expansion, resin, grout, or friction.

Challenges and solutions

While rock bolts are highly effective, their performance depends on factors such as rock type, installation quality, and environmental conditions. Common challenges include corrosion and improper anchoring. These issues can be mitigated by:

- Make use of materials that are resistant to corrosion, such as stainless steel or galvanized bolts.

- We conduct thorough geological surveys to determine the optimal type and placement of bolts.

- Ensuring proper installation practices to maximize effectiveness.

Conclusion

Rock bolt are a cornerstone of modern underground construction, offering unparalleled stability and safety in challenging environments. Their ability to reinforce rock masses makes them indispensable in tunneling, mining, and other geotechnical projects.

By understanding the role of rock bolts, engineers and project managers can ensure the success of their underground construction endeavors. With proper selection, installation, and maintenance, these systems provide a reliable and cost-effective solution for years to come.

Post Comment