Choosing the Right Cable for Your Submersible Pump: A Comprehensive Guide

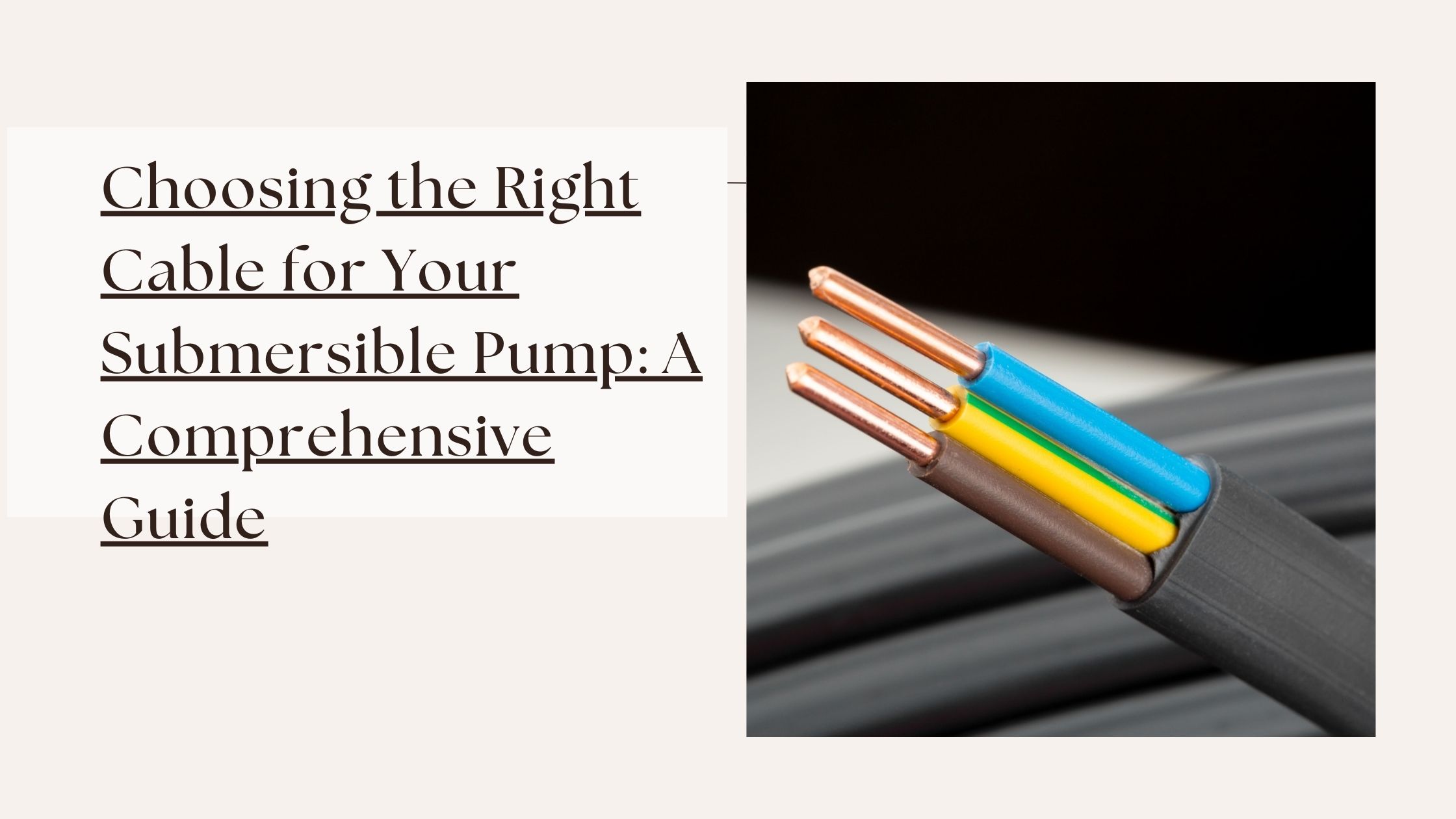

Selecting the suitable cable is as important as picking the pump itself for assuring the maximum performance and toughness of your submersible pump. The gathering of varieties and standards may be daunting, predominantly for someone without understanding with electrical components.

The suitable cable not only facilitates efficient power transfer but also improves the safety and dependability of your pump under challenging underwater conditions. This post will examine types of submersible Flat cables from a reputed supplier.

Characteristics of cables from a reputed submersible Flat cables manufacturers

Superb resistance to water, moisture, abrasion, grease, and oil

Extended flexibility lifespan

Superb mechanical and electrical characteristics

Choosing the appropriate cable for your submersible pump is essential for ensuring safety, efficiency, and durability due to its vital uses. The cable functions as a conduit, delivering electricity to the pump while safeguarding it from the severe underwater conditions.

Our detailed review will provide you with the necessary information to comprehend cables, insulation kinds, and safety requirements for making an best selection.

Categories of Submersible Pump Cables

Submersible pump cables are available in many forms and specifications, each tailored for particular uses. The primary categories encompass:

1. Flat Submersible Pump Cable

The flat submersible pump cable is among the most prevalent forms of submersible pumps. This kind is recognized for its compact size and adaptability, rendering it suitable for applications requiring the cable to be positioned flat on the surface. It is often used in wells and boreholes, where spatial constraints exist.

2. Flat Jacketed Submersible Pump Cable

The flat jacketed submersible pump cable has an additional layer of protective material to safeguard against external damage. This cable is optimal for installations subjected to environmental variables such as moisture, chemicals, or mechanical stress.The flat jacketed submersible pump cable is capable of accommodating diverse loads and temperatures, rendering it appropriate for deep well pumps functioning at significant depths where pressure and corrosive materials are considerations.

3. Twisted Submersible Pump Cable

Twisted submersible pump cables use twisted conductors that decrease the risk of tangling or knotting, hence maintaining optimal and efficient performance. These cables are appropriate for deep-well applications necessitating flexibility and durability against mechanical wear.Moreover, the entangled wires may generate hotspots that increase the likelihood of insulation failure, possibly resulting in short circuits or electrical fires. To avoid such issues, it is essential for engineers and technicians to follow best practices during installation, ensuring that wires are meticulously arranged and properly connected to prevent torsion.

4. Submersible Pump Core Cable

A 3-core cable for submersible pumps is often used in systems necessitating three-phase power, rendering it appropriate for high-power applications. These cables can accommodate higher current loads, making them suitable for industrial applications and extensive water pumping systems.

5. Submersible Pump Cable

Submersible water pump cables are engineered to accommodate the substantial power requirements of water pumps while exhibiting resistance to water, oils, and chemicals. These cables are crucial for guaranteeing the safe functioning of water pumps in deep wells or other submersible systems.

Significance of Selecting the Appropriate Cable

When you select the best cable from the submersible Flat cables manufacturers a question of convenience; it is a critical choice that might affect the performance, security, and robustness of the complete system. A submersible pump is normally immersed in water, representing it functions in the situation where moisture and other impurities might damage electrical components.

This increased exposure necessitates the selection of a cable that is both robust and particularly engineered to endure such circumstances. The appropriate cable will provide excellent conductivity, enabling your pump to function efficiently and effectively.

Insufficiently thick cables may cause voltage dips, leading to diminished pump efficiency and heightened energy use. Conversely, excessively thick wires may be cumbersome and difficult to handle, adding superfluous complexity to your configuration.

Importance of Cable Quality in Submersible Pump Performance

The quality of the cable used in your submersible pump directly affects its overall performance and lifespan. High-quality cables are designed to withstand harsh conditions such as constant exposure to moisture, pressure, and chemicals found in water sources. By selecting cables with superior insulation materials and protective coatings, you can prevent issues such as short circuits, overheating, or even cable failure. Additionally, premium cables improve the energy efficiency of the pump, reducing energy consumption and operational costs over time. Investing in quality cables ensures not only the reliable operation of your submersible pump but also minimizes maintenance and replacement needs.

Post Comment