Stainless Steel Market Share, Size, Growth & Insights | 2032

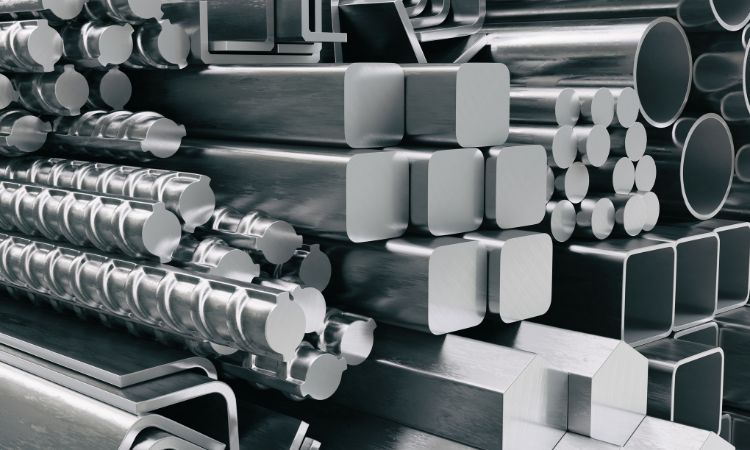

The global Stainless Steel Market Size has become an essential sector in modern industry, reaching a value of approximately USD 153.26 billion in 2023. As a versatile material known for its corrosion resistance, durability, and aesthetic appeal, stainless steel is used in a wide range of applications, including construction, automotive, electronics, and kitchenware. With an expected compound annual growth rate (CAGR) of 6.8% from 2024 to 2032, the market is projected to reach nearly USD 277.05 billion by 2032. This article delves into the key benefits, industry developments, driving and restraining factors, market segmentation, and regional insights, along with an analysis of trends and opportunities.

Key Benefits of Stainless Steel

Stainless steel offers numerous advantages that contribute to its widespread use:

- Corrosion Resistance: Stainless steel’s inherent resistance to rust and corrosion makes it ideal for harsh environments, including chemical processing and marine applications.

- Durability: With high tensile strength, stainless steel can withstand significant wear and tear, ensuring longevity and reducing replacement costs.

- Aesthetic Appeal: The sleek and modern appearance of stainless steel makes it a popular choice for architectural and design applications.

- Hygienic Properties: Stainless steel is easy to clean and sterilize, making it suitable for the food and healthcare industries.

- Recyclability: As a sustainable material, stainless steel is 100% recyclable, contributing to reduced waste and environmental impact.

Key Industry Developments

The stainless steel market has witnessed several noteworthy developments:

- Technological Advancements: Innovations in production techniques, such as the development of electric arc furnaces and improved alloy compositions, enhance the efficiency and quality of stainless steel production.

- Increased Demand in Emerging Markets: Rapid industrialization in countries like India and China has spurred demand for stainless steel in construction and manufacturing.

- Sustainability Initiatives: A growing focus on sustainability has prompted manufacturers to invest in eco-friendly practices and recycled materials.

- Product Diversification: The introduction of specialty stainless steel grades tailored for specific applications, such as high-temperature or low-alloy stainless steels, is expanding the product range available in the market.

Driving Factors

Several factors contribute to the growth of the stainless steel market:

- Construction and Infrastructure Development: The ongoing global urbanization and infrastructure projects drive demand for stainless steel in construction, as it is a preferred material for structural and architectural applications.

- Automotive Industry Growth: The automotive sector increasingly utilizes stainless steel for exhaust systems, fuel tanks, and structural components due to its strength and resistance to high temperatures.

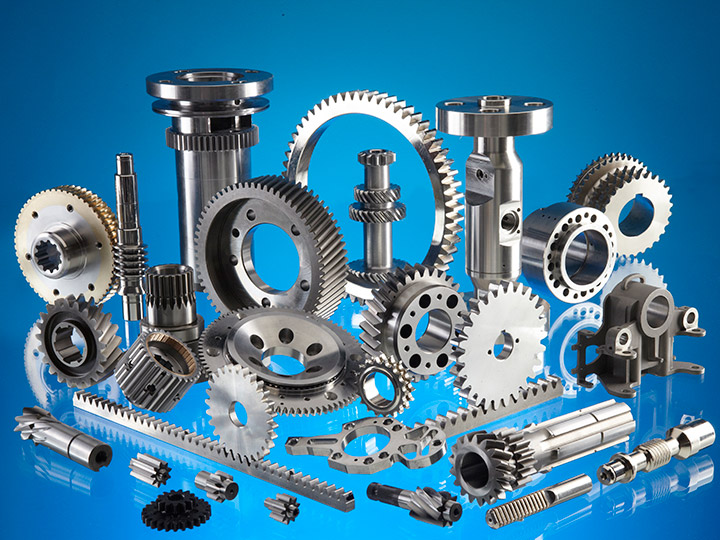

- Industrial Machinery Demand: Stainless steel’s durability and corrosion resistance make it an ideal choice for various industrial machinery and equipment.

- Consumer Goods Market: The rising demand for stainless steel cookware, cutlery, and appliances is bolstered by consumer preferences for durable and aesthetically pleasing products.

Restraining Factors

Despite its many advantages, the stainless steel market faces certain challenges:

- Price Volatility: Fluctuations in the prices of raw materials, such as nickel and chromium, can impact production costs and market stability.

- Competition from Alternatives: The availability of alternative materials, such as carbon steel and plastics, can pose a challenge to the stainless steel market.

- Environmental Regulations: Stringent regulations regarding emissions and waste management in stainless steel production may increase operational costs for manufacturers.

Market Segmentation

The stainless steel market can be segmented based on various criteria:

1. Type

- Austenitic: The largest segment, known for its excellent corrosion resistance and formability.

- Ferritic: Known for good corrosion resistance and lower cost, primarily used in automotive and architectural applications.

- Martensitic: Valued for its hardness and wear resistance, often used in cutlery and tools.

- Duplex: Combines properties of austenitic and ferritic steels, offering enhanced strength and corrosion resistance.

2. Application

- Construction: Utilized for structural applications, roofing, and facades.

- Automotive: Used in various components like exhaust systems and chassis.

- Consumer Goods: Encompasses kitchenware, appliances, and cutlery.

- Industrial Equipment: Used in machinery, storage tanks, and piping systems.

- Medical Devices: Essential for surgical instruments and equipment.

3. Region

- North America: Significant market driven by construction and automotive sectors.

- Europe: Established industry with a focus on innovation and sustainability.

- Asia-Pacific: The fastest-growing market, spurred by rapid industrialization in countries like China and India.

- Latin America: Emerging market with increasing demand in construction and consumer goods.

- Middle East and Africa: Growth driven by infrastructure projects and oil & gas industries.

Market Outlook

The stainless steel market is poised for substantial growth over the coming years. As industries increasingly prioritize durability, sustainability, and aesthetics, stainless steel will remain a material of choice. The forecasted CAGR of 6.8% indicates robust demand, particularly in emerging economies where infrastructure and industrial growth are accelerating.

Trends

- Sustainability: The shift towards eco-friendly production processes and increased use of recycled materials will shape the industry landscape.

- Smart Manufacturing: Adoption of Industry 4.0 technologies, such as IoT and automation, will enhance production efficiency and quality control.

- Customization: Growing demand for specialized stainless steel products tailored to specific applications will drive innovation.

Industry Segmentation

The stainless steel market’s industry segmentation reveals a diverse landscape characterized by various end-users and applications. Key players in the market are continuously adapting to changing consumer preferences and technological advancements. The focus on sustainability and recycling is also influencing industry dynamics.

Regional Analysis/Insights

North America

North America is a mature market for stainless steel, driven by a strong construction sector and the automotive industry’s recovery. The United States is the leading consumer, with significant investments in infrastructure projects.

Europe

Europe is known for its high-quality stainless steel production, with countries like Germany and Italy leading in manufacturing. The emphasis on sustainable practices and innovation contributes to the region’s growth.

Asia-Pacific

The Asia-Pacific region is the fastest-growing market, propelled by rapid industrialization and urbanization. China and India are key players, with significant demand for stainless steel in construction, automotive, and consumer goods.

Latin America

Latin America is witnessing growth due to increasing infrastructure investments and rising disposable incomes. The demand for stainless steel in construction and consumer goods is expected to drive market expansion.

Middle East and Africa

The Middle East and Africa are emerging markets for stainless steel, with growth driven by infrastructure projects in countries like the UAE and South Africa. The oil and gas sector also contributes significantly to stainless steel demand.

Analysis and News

Recent news in the stainless steel market highlights the impact of geopolitical factors on raw material prices and supply chains. Trade policies, tariffs, and environmental regulations are crucial elements influencing market dynamics. Companies are increasingly focusing on sustainability initiatives to mitigate risks and align with global environmental goals.

Top Impacting Factors

Several factors significantly impact the stainless steel market:

- Raw Material Prices: Fluctuations in the cost of nickel, chromium, and other alloying elements directly affect production costs.

- Technological Advancements: Innovations in production processes enhance efficiency and product quality, influencing market competitiveness.

- Consumer Preferences: The growing demand for sustainable and aesthetically pleasing products shapes the direction of the stainless steel industry.

- Regulatory Environment: Compliance with environmental regulations impacts operational costs and market dynamics.

Target Audience

The target audience for the stainless steel market includes:

- Manufacturers: Companies involved in the production of stainless steel products for various industries.

- Distributors and Wholesalers: Entities engaged in the distribution of stainless steel to end-users.

- End-Users: Industries utilizing stainless steel in construction, automotive, consumer goods, and healthcare.

- Investors: Stakeholders interested in the growth potential and profitability of the stainless steel sector.

Major Key Players

Some of the prominent players in the global stainless steel market include:

- Nippon Steel Corporation

- AK Steel International B.V.

- Outokumpu Oyj

- POSCO

- Aperam SA

- Beihai Chengde Group

- JFE Steel Corporation

- Baosteel Stainless Steel Co.,Ltd

- Acerinox S.A.

- Tata Steel Limited

- Others

Opportunities and Challenges

Opportunities

- Rising Demand for Green Building Materials: The trend towards sustainable construction materials presents growth opportunities for stainless steel manufacturers.

- Technological Innovations: Advancements in production methods can lead to cost reductions and improved product offerings.

- Expanding Applications: New applications in emerging industries, such as renewable energy and electric vehicles, provide avenues for growth.

Challenges

- Global Economic Uncertainty: Economic fluctuations and geopolitical tensions may disrupt supply chains and impact market stability.

- Competition from Alternative Materials: The emergence of alternative materials can challenge the market share of stainless steel.

- Regulatory Compliance: Adhering to environmental regulations may increase operational costs for manufacturers.

Post Comment