How Semiconductor Part Repair Services Can Reduce Downtime & Costs

Services that do repair jobs on semiconductor parts are essential to either conserving equipment downtime radius or fewer money-spending. This is a great way to keep your equipment working fine and reduce costs, as any damaged part can be repaired then and there and replacement, which is costly, avoided.

By getting their services on board and investing in them, your equipment will run better and less often, with a very tiny chance of spontaneous downtime on you, thereby saving money: operational efficiency thus improved; cost-effective, worth the while.

Understanding the Basics of Semiconductor Part Repair Services

Repair services for semiconductor parts are the best way to save cost, in equipment failure, and downtime. This involves fixing and refurbishing semiconductor parts used in the field of electronic, aerospace, and cars, thus making repair and, also, refurbishment of semiconductor parts very useful in contributing to their effectiveness and reliability.

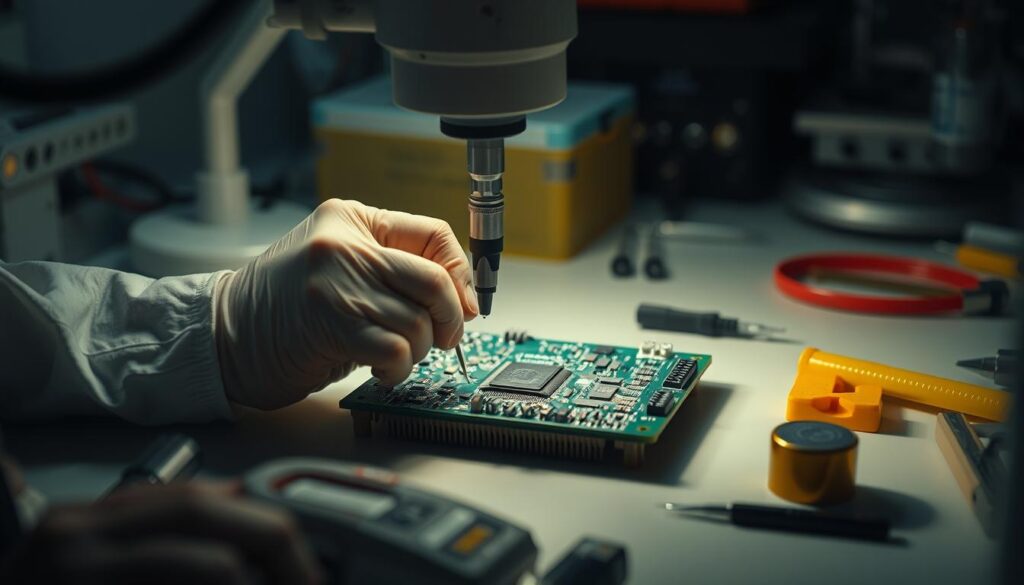

Repair begins with the very basic analysis to know the cause of failure. Cleaning followed by replacing damaged parts. Experts use all special repair tools and techniques for repairs.

Among semiconductor parts, microprocessors, memory chips, and power devices need repairs. Heat, electrical faults, and physical damage could lead to their failures. Repair services make it functional and recover it as new.

Common Failure Modes

Knowing common failure modes and damage patterns is key for effective repairs. This involves looking at the part’s design, materials, and how it’s used. It helps spot weaknesses and vulnerabilities.

Importance of Professional Expertise

Extreme Damage to Components-Problems with Repairs. Today, many complicated components can only be repaired by professionals. Certain procedures and gadgets are used to find and fix a problem. When the work is done, the component will surely come back to life and work properly.

The Economic Impact of Equipment Downtime in Semiconductor Manufacturing

The fast fixing of semiconductor devices needs to be on the pale even to costly downtime. Such downtime means lost production, reduced revenues, and expensive maintenance. Evidence in the U.S. semiconductor industry proves the importance of any downtime as that poses a risk to big trouble.

To start with, there would be huge financial losses due to the malfunction of equipment. Hence speed of impact repairs was mainly meant for boosting up companies’ coffers and productivity plus keeping them in the rat race on the world scene. This makes apparent the broad potential need for excellent maintenance and repair services.

In the world of semiconductors, downtime affects not only the manufacturer but also suppliers and customers. Therefore the financial damage incurred due to downtime shows the need for an investment in repair and maintenance. By investing time in repair and maintenance, organizations can prevent failure, avoid downtime, and run smoothly.

Advanced Diagnostic Techniques in Semiconductor Repair

A touch finds the exact problem with the silicon chip component. Advanced methods are used by a world-class semiconductor repair service to very much do this. They will examine a tremendous deal of the outside surface of their component plus the inside.

Surface Analysis Methods

Scanning electron microscopy and energy-dispersive spectroscopy are few tools used to look into the surface. They help in detecting damage or dirt that could be a cause for embarrassment. Hence they also help in locating cracks or corrosion which are responsible for the failure of a component.

Internal Component Testing

Another principal point of testing is to investigate the inside of the component. Special equipment carries out the check on the circuitry for different issues, and tests include performance working and reliability.

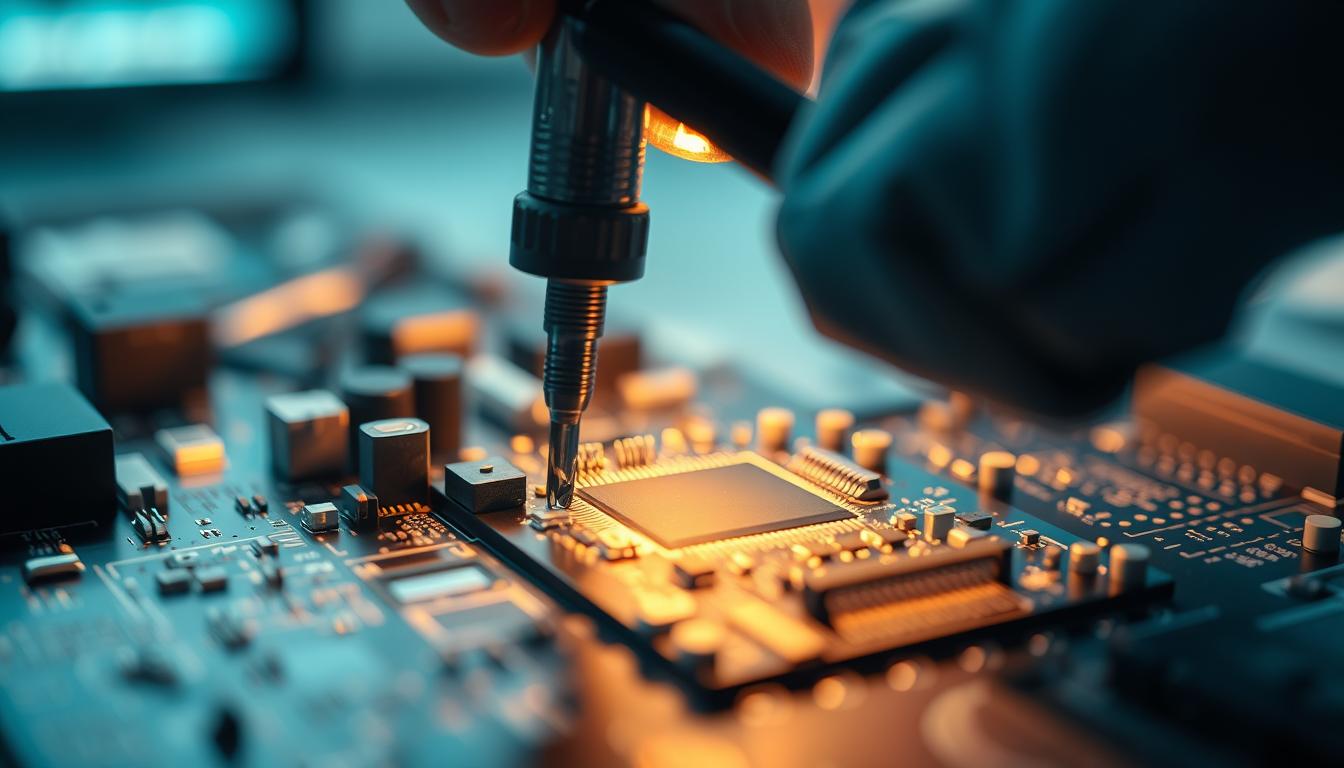

Modern Semiconductor Part Repair Technologies

The solutions related to semiconductor repair have evolved tremendously. The use of the latest technologies will help reduce downtime and costs by a great margin. The advanced repair services extend their support to complex semiconductor parts that would help them last longer and reduce waste.

These technologies work upon upgrading methods to find and repair problems on parts. Essentially, repair services resolve issues in a quick time.” Hence, in less time and money, manufacturers get into work more quickly, and the repair would cost them less.”

Further, application of these high-tech repair technologies makes the equipment more reliable and efficient with satisfied customers and lower maintenance costs. While the demand for these services is increasing, manufacturers must keep up with the latest technological advancements.”

Cost-Benefit Analysis of Professional Repair vs. Replacement

Often, companies face a difficult decision between amino fixing or replacing semiconductor parts. However, this choice highly impacts their finances. They have to think really hard about costs and benefits to make the best decision.

Initial Investment Considerations

Making parts can prove to be a cheaper option than buying new ones. This is the case, even with expensive ones. Mechanically, this means saving on costs while buying new in favor of a little bit of repair, and on top of that, a somewhat better use of resources for each project in hand.

Long-term Financial Benefits

Repairing parts can save money over the years. And by extending the longevity of such components, replacement costs become less frequent. This also means less time lost waiting for repairs, and a great deal more work getting done.

ROI Calculations

Also, to assess the return on investment, it is customary for companies to consider savings and productivity. This will give them a better idea of whether repair is the right choice. In this way, they can make smart decisions to keep their expenditures down and thrive in the long term.

Quality Assurance in Electronic Component Repair

Quality assurance in electron test and repair is of prime importance within the repair procedure to ensure the usefulness and reliability of the repaired parts. The repair process consists of various tests to examine the salubriousness of the parts under consideration.

The repair procedure has strict quality checks involving visual inspection of the parts; it also includes electrical tests and tests done under different conditions to catch defects early in the process so that the manufacturer can prevent any downtime and minimize maintenance costs.

To semiconductors, quality checks are vitally important to ensure perfect functioning and expected performance from the devices. Here’s where skilled laborers, special tools, and detailed tests come to be in use. Quality focus can benefit manufacturers in keeping their parts operating optimally.

Implementing a Preventive Maintenance Strategy

Preventive maintenance would, thus, assure minimum downtime or minimization of maintenance costs. When the equipment goes down, the ailing equipment requires continuous monitoring to bring the faults to a minimum so that any stress does not turn into failure. The automation of early warning systems provides quick adjustments once a malfunction is detected.

Nowhere else is this scheme best employed than in the recovery operations of semiconductor manufacturing. It ensures the maintenance of proper equipment and avoids the root cause of major repairs.

But maintaining records on that general machine performance is very important since it ensures efficient tracking and pinpointing show areas for the proposition of cure. This information will further enhance the efficiency of the proposed preventive maintenance programme to conform to the act of equipment and the required process parameterization for its operation. Chip repair services and semiconductor solutions could ensure more maintenance effectiveness.

Scheduled Inspection Protocols

Regular checks are part of preventive maintenance. Such checks can look for problems before they start. This, in turn, provides manufacturers with an opportunity to rectify the issues quite early in time, so as to avoid breakdowns and hence downtime.

Early Warning Systems

Yet another function is performed by the early warning systems. These systems keep a watch-focused equipment in operation, thus starting to trouble as soon any indication arises. This allows manufacturers to take corrective action to prevent failures and downtime.

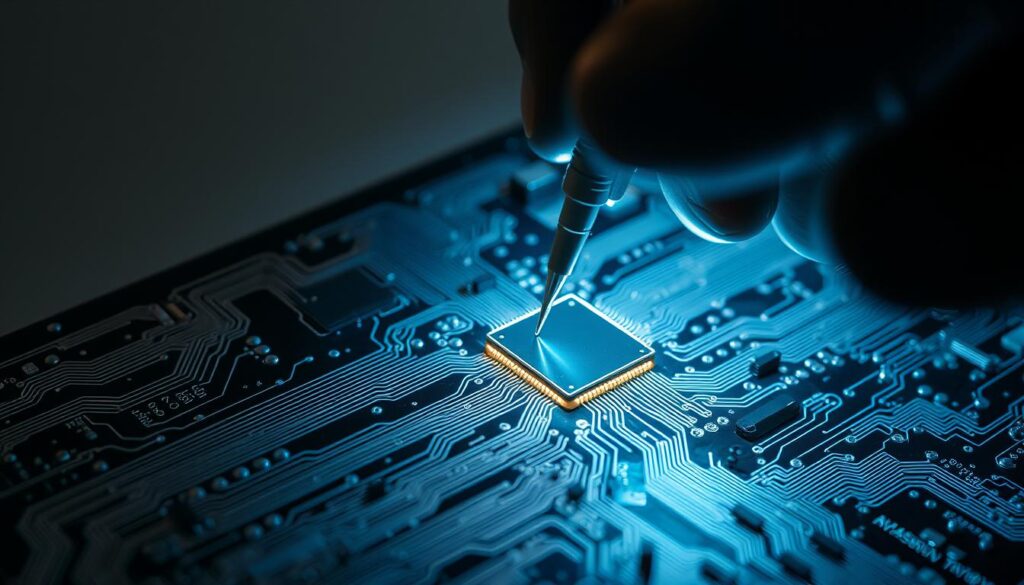

Silicon Chip Repair Techniques and Methodologies

Semiconductor part repair services are key in keeping manufacturing running smoothly. They help reduce downtime and costs. Silicon chip repair uses the latest tech to fix chips, making them work perfectly.

Fixing silicon chips involves a detailed look at their structure and how they work. Then, special techniques are used to fix or replace damaged parts. Experts at repair services make sure the chips work as they should.

Using the newest repair methods helps manufacturers save time and money. It also makes their work more efficient.

In the USA demand for semiconductor repair services is on the rise. While manufacturing increases, so do the needs for these repairs. Investing in new tech ensures chips are able to be fixed well, which in turn reduces chances of problems later on.

Choosing the Right Semiconductor Repair Service Provider

Choosing a trustworthy service provider for electronic component repair is a very important process involved with refurbishing semiconductor components needs specialized skills as well as equipment.

A trusted expert can help in reducing the downtime while curbing costs from equipment failure. Several companies in the U.S. are truly into electronic component repair and semiconductor refurbishing, but not all can be equal when it comes to quality and expertise.

Thus, it is critical to verify the certification, experience, and technical ability of the service provider. It is also vital to look into the service provider’s experience with complex repair projects. The overall performance and life span of equipment will greatly depend on how well they have done in refurbishing semiconductor components.

Thus, it is safe to choose the service provider if it has a clean and good record of accomplishment in taking care of equipment. Then, one can talk about the technical capabilities while choosing a semiconductor repair service provider. A service provider must, this time, work with the latest equipment and a skilled technical team who do everything from surface analysis to internal component testing.

Considering these factors helps the companies with wise decision-making and choosers of service providers in accordance with their requirements and budget.

Environmental Considerations in Component Refurbishment

Due to rapid growth in the demand for electronic devices, environmental issues connected with their production are very acute and important indeed. The production of next-generation semiconductors is highly intensive in resource and energy input and, therefore, causes higher amounts of greenhouse gas emissions and generates a lot of electronic waste.

Repairing a semiconductor device, on the other hand, is a green solution. This cuts down on the need for new materials and waste. This way, companies can lower their carbon footprints and save the environment.

Within this concept, the silicon chip repair service plays a very important role. It enables companies to repair current chips as opposed to making new ones. Thereby saving resources available and reducing electronic waste.

Refurbished chips can be used for many things ranging from gadgets to industrial tools. Therefore, fewer new energy-demanding devices would be built.

Thus, environment-friendly repair companies save money, appreciate their public image, and comply with stricter environmental regulations. As the global tech world expands, so will the demand for this form of green repair.

Industry Standards and Compliance Requirements

Works on the repairing of semiconductors mainly concern themselves with strict regulations and laws to ensure quality services rendered. The ISO certification is an important standard that chews on the quality management framework.

Companies that abide by these standards testify before the whole world of their dedication to quality repair solutions. It also goes further by contexts to regulating safety measures taken inside a company and environmental concerns during the repair of semiconductor devices. This is very crucial because it basically dictates what rules are to be adhered to in repair jobs for semiconductor devices.

These regulations ensure that no repairs being done are environmentally hazardous and must at least safeguard the environment by reducing as much pollution as possible. Therefore, by complying with regulations and standards set forth in the semiconductor repair industry, companies within the sector lower environmental impacts and evade legal troubles. Also needed by companies are quality management systems.

Such systems will ensure that repair services are made consistent and reliable; they describe everything from the initial inspection to the final testing. These systems allow companies to enhance their quality while working on minimizing defects. In summary, the semiconductor repair industry has very many standards and regulations within which to operate.

Abiding by these will act as a guarantee for high-quality repairs and less effect on the environment. Japan-based companies working along these standards will offer proofs of their commitment toward quality and sustainability.

Emerging Trends in Semiconductor Device Repair

The repair services for semiconductors are changing to meet better and cheaper fixes. New methods and tools have joined hands to make repairs fast and cheap, enabling companies to work more efficiently and, subsequently, save money by doing so.

Such repair service significantly reduces electronic waste and makes the manufacturing process less toxic to the environment. Given the industry’s growth, there will be greater and greater demand for reliable repair services, and thus innovation to provide such electronics with effective repairs. To minimize it pretty diametrically: the future of semiconductor repairing is about efficiency, cost-effectiveness, and safety for the people and the planet.

Thus, keeping track of the latest in repairing services is one way for the companies to cope with competition. Staying updated about the new changes in this area is quite essential.

Case Studies: Successful Implementation of Repair Programs

Repair programs are an effective way to help in minimizing downtime and repairs for the chip-makers. Better efficiency and savings can even be attained by working with trusted repair service providers. This is due to refurbishing semiconductor components and repairing devices inside the factory.

Many in the manufacturing business are already realizing great dividends from repair programs. A leading chip manufacturer, for instance, was able to reduce their downtime by 30%. They also avoided huge repair charges through the refurbishment program worth millions.

Manufacturing Sector Examples

In the arena of manufacturing, fixing semiconductor devices is key to make equipment run in a smooth manner. Investment in refurbishing various components will extend the life of equipment, thus reducing the necessity for costly new parts.

Research Facility Applications

Research establishments also benefit from the fixing of semiconductor devices and refurbishment of components. Partner with a competent repair service so that all your equipment is always in excellent working condition. This equals better research results with lost time reduced to the minimum.

Cost Savings Analysis

Research claims that repair programs save quite a bit for firms. Cutting downtime and keeping machines alive longer means BIG money saved on repairs and replacements. Therefore, repairing and refurbishing semiconductors is a judicious decision.

Building an Effective Repair Management System

The establishment of an effective repair management platform is one critical way to create minimum downtime and achieve maximum efficiency when producing semiconductors. A repair management system observes the maintenance at an early stage, checks and controls the quality of the repair, and also enables coordination with the supply chain. In other words, chip manufacturers can keep machines from breaking down by making full use of the silicon chip repair service.

A first-rate repair system warrants well-thought-out solutions built around the unique needs of each factory. This allows for routine checks on the spot, repairs, or replacements if something breaks down. A proactive approach is meant to lower the costs, improve product quality, and increase customer satisfaction.

Good repair management also means planning ahead and maintaining smooth relationships with suppliers and contractors alike. This would ensure parts and skills are in place, resulting in minimum downtime and ramped-up efficiency. By adding chip repair service to their structure, makers get to run the production smoothly and hence save.

Investing in a comprehensive repair management system could give semiconductor makers an increase in profits, boost product quality, and develop a solid position in the marketplace. By deploying proper repair management on the part of factories, downtimes could be cut short, money spent, and performances improved.

The Future of Semiconductor Repair Solutions

Because of the rapid changes in the semiconductor landscape, incremental repairs, and fixes, in a way, will also have to evolve into more AI and machine learning-driven technologies to make the repairs faster and accurate.

The other thing is the future itself, whereby what goes to the making of the actual semiconductors and the newest materials will again guide the path of repair services. Which in turn means equipping, skillfully training their workforce, and advancing their repair and diagnostic technology, offering high-quality work to further minimize these stoppages? But it won’t just be technological advances that determine the future; repair services will also have to be flexible and offer customized solutions to their clients.

This might mean repairing an array of semiconductor components and providing continuous support. Companies, in such a case, will end up serving their clients better by keeping disruptions to a minimum.

Conclusion

The semiconductor industry is moving fast; therefore, there will always be a need for reliable repair services for electronic components. New silicon chip repair technologies make repairs efficient and cost-effective. Companies and research centers could have specialized repair services to have longer service for their semiconductor assets.

Therefore, it reduces the time lost which increases profits. With a trusted repair service, they could be ahead of others and be successful in the long run. The semiconductor repair is bright. With new technology and practices, companies will gain maximum use of their components, ensuring that they are productive and competitive in the fast-changing marketplace of semiconductor technology.

Post Comment