Roofing Machines: Types, Benefits, and How They Boost Efficiency

The roofing industry has seen remarkable advancements in recent years, and at the heart of this transformation are roofing machines. These powerful tools are revolutionizing how contractors, builders, and manufacturers approach roofing projects by improving speed, precision, safety, and overall efficiency. Whether you’re involved in residential, commercial, or industrial roofing, understanding the role of roofing machines can help streamline your operations and elevate the quality of your work.

What Are Roofing Machines?

Roofing machines are specialized equipment designed to automate or assist in the installation, fabrication, or repair of roofing systems. They reduce manual labor, minimize material waste, and enhance precision. Roofing machines can range from portable roll formers to stationary panel benders and seaming machines.

Depending on the roofing system and material—such as metal, asphalt, or composite—different machines are used for bending, cutting, forming, or fastening panels and shingles.

Types of Roofing Machines

There are several categories of roofing machines tailored for specific applications. Let’s take a closer look at the most commonly used types:

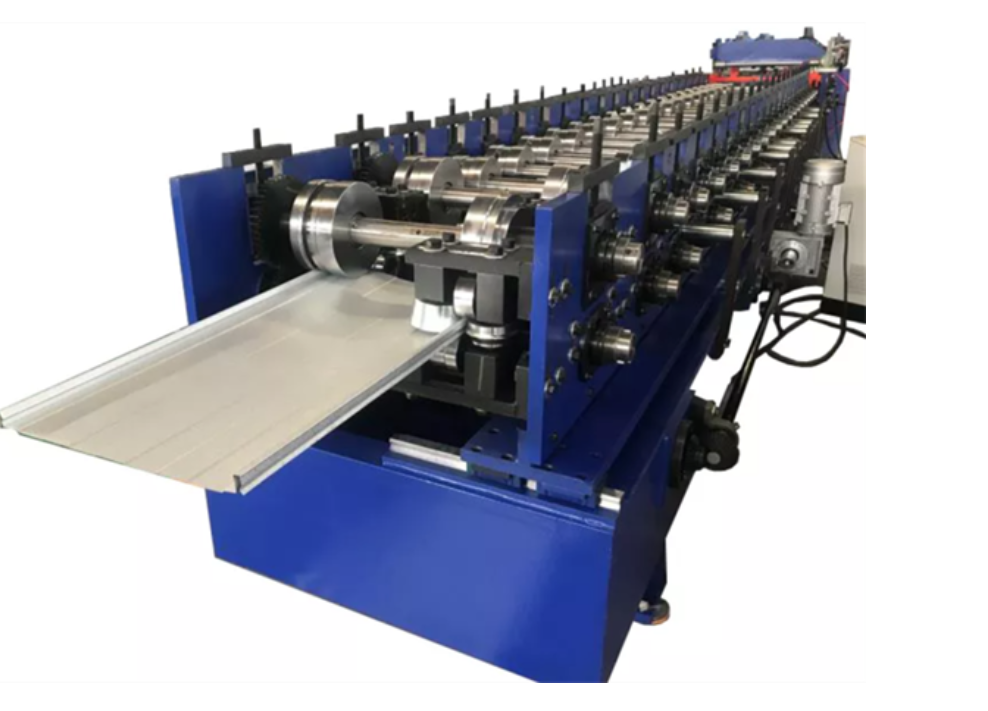

1. Roll Forming Machines

Roll forming machines are used to shape long strips of metal into specific roofing profiles, such as standing seam panels or corrugated sheets.

Key Features:

- Custom panel lengths on-site

- Reduces transportation and material waste

- Ideal for large-scale metal roofing projects

2. Seaming Machines

Seaming machines are used to lock panels together, especially in standing seam metal roofing systems. They ensure waterproof and wind-resistant seams.

Key Features:

- Ensures tight and secure joints

- Speeds up installation

- Reduces risk of leaks

3. Panel Curving Machines

These machines curve metal panels to fit arched roofs or decorative applications. They can produce convex or concave bends, depending on the design.

Key Features:

- Supports complex architectural designs

- Maintains structural integrity during bending

4. Panel Shears and Slitters

Shears and slitters are used to cut metal panels to custom widths and lengths with high precision, minimizing jagged edges or waste.

Key Features:

- Accurate cuts for tight-fitting panels

- Reduced need for rework

- Improves material efficiency

5. Drip Edge Machines and Trim Roll Formers

These machines create roof trims, drip edges, and other accessories that complement panel systems, helping complete the roofing structure.

Key Features:

- Custom trim production on demand

- Enhances weather resistance and aesthetics

6. Gutter Machines

Though not directly part of the roof surface, gutter machines are essential for creating seamless gutter systems that manage water drainage effectively.

Benefits of Using Roofing Machines

Integrating roofing machines into your operation offers significant advantages across all stages of a roofing project.

1. Increased Efficiency

Roofing machines dramatically reduce the time required to fabricate and install panels. On-site roll forming, for example, eliminates wait times for prefabricated panels and speeds up large-scale installations.

2. Improved Accuracy and Consistency

Manual cutting or forming can lead to errors and inconsistencies. Machines ensure uniform dimensions, straight edges, and tightly sealed seams—leading to higher-quality results.

3. Reduced Labor Costs

With machines taking on more of the heavy lifting, fewer laborers are needed, and the risk of injury is reduced. This allows contractors to allocate skilled workers more efficiently.

4. Customization and Flexibility

Modern roofing machines allow operators to customize panel length, width, and profile directly on-site. This is especially helpful for:

- Complex roof designs

- Custom orders

- Reducing material waste

5. Portability and On-Site Fabrication

Many modern machines are designed for mobility, allowing contractors to bring them directly to the job site. This cuts down on transportation costs and ensures a faster turnaround.

6. Durability and Low Maintenance

Most commercial roofing machines are built from high-grade steel and require minimal maintenance, ensuring long-term reliability even in demanding environments.

How Roofing Machines Are Changing the Industry

The roofing industry is increasingly shifting toward automation and precision fabrication, and roofing machines are leading this change. Here’s how:

✅ Faster Project Completion

Machines dramatically shorten production and installation timelines, which means contractors can complete more jobs in less time—translating to greater revenue.

✅ Higher Quality Standards

As competition increases, clients expect precision, clean lines, and watertight seams. Roofing machines meet these demands, helping professionals maintain a strong reputation.

✅ Sustainability and Waste Reduction

On-site fabrication helps reduce material waste and carbon emissions from transporting prefabricated panels. This aligns with green building practices and helps companies meet sustainability goals.

✅ Scalability for Businesses

Investing in roofing machines allows businesses to take on larger and more complex projects without drastically increasing labor costs. This supports business growth and diversification.

Considerations When Choosing a Roofing Machine

Before investing in roofing machinery, consider the following:

- Type of projects: Are you primarily working on residential homes, commercial buildings, or industrial sites?

- Material compatibility: Ensure the machine can handle the metal type (steel, aluminum, copper) and thickness you plan to use.

- Ease of operation: Look for user-friendly interfaces and support documentation.

- Portability: Mobile units offer flexibility for on-site jobs.

- Warranty and service: Choose manufacturers that offer good customer support and training.

Conclusion

Roofing machines have become an essential tool for modern contractors and manufacturers looking to increase efficiency, reduce costs, and deliver higher-quality roofing solutions. From roll formers and seamers to panel curvers and shears, these machines not only streamline production but also open the door to custom designs and faster job turnaround.