How to Optimize Your Warehouse Layout with Mobile Compactor Storage Systems

In today’s fast-paced business environment, efficient use of space is paramount, especially in warehouse operations. As e-commerce continues to grow and consumer demands evolve, businesses must adapt their storage solutions to maximize efficiency and minimize costs. One innovative solution that has gained traction in recent years is the mobile compactor storage system. In this blog, we will explore how to optimize your warehouse layout using these systems, highlighting their benefits and features, and the importance of partnering with reputable Mobile Compactor Manufacturers.

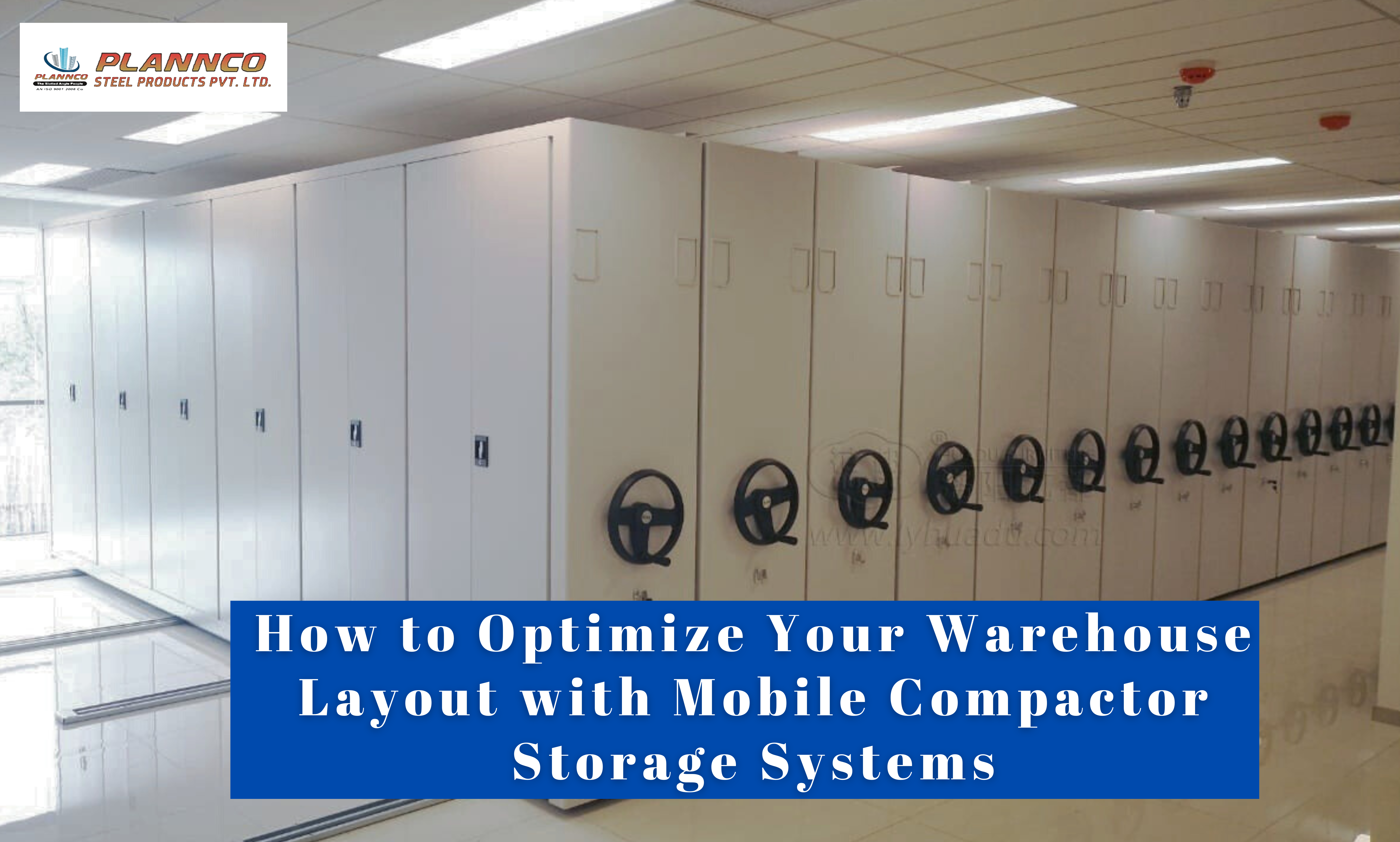

Understanding Mobile Compactor Storage Systems

Before diving into optimization strategies, let’s understand what mobile compactor storage systems are. These systems are designed to store materials compactly, allowing for adjustable aisles. Essentially, they consist of shelving units mounted on wheeled bases that can be moved to create or eliminate aisles as needed. This flexibility enables businesses to maximize their storage capacity within the same square footage.

Key Benefits of Mobile Compactor Storage Systems

- Space Efficiency: One of the most significant advantages of mobile compactors is their ability to maximize storage space. By eliminating fixed aisles, these systems can increase storage density by up to 50%.

- Improved Accessibility: Mobile compactors allow you to access all stored items without having to navigate through multiple aisles. This enhances workflow and reduces the time spent searching for items.

- Versatility: These systems can accommodate a variety of items, from documents to heavy Pallet Rack, making them ideal for various industries, including retail, manufacturing, and distribution.

- Enhanced Safety: Mobile compactor systems can reduce the risk of accidents by minimizing clutter and ensuring that materials are stored securely.

- Cost-Effective: By maximizing storage efficiency and reducing the need for additional warehouse space, mobile compactor systems can lead to significant cost savings.

Steps to Optimize Your Warehouse Layout with Mobile Compactor Storage Systems

Now that we understand the benefits of mobile compactor storage systems, let’s explore how to optimize your warehouse layout with these innovative solutions.

Step 1: Assess Your Current Warehouse Layout

Before making any changes, it’s essential to evaluate your current warehouse layout. Take the time to map out your space and identify areas that are underutilized or cluttered. Consider the following questions:

- How much storage space do you currently have, and how much is being used?

- Are there areas where items are difficult to access?

- What are the common workflows within your warehouse?

This assessment will provide a solid foundation for optimizing your layout with mobile compactors.

Step 2: Define Your Storage Needs

Every warehouse has unique storage requirements. Before implementing a mobile compactor storage system, it’s crucial to define your specific needs. Consider the following factors:

- Type of Items: What types of products will you be storing? Are they heavy, light, bulky, or standard-sized?

- Inventory Turnover: How often do you receive and ship out products? High-turnover items may require different storage solutions compared to low-turnover items.

- Access Frequency: Determine how often different items need to be accessed. Place frequently picked items in easily accessible locations

Step 3: Design Your Mobile Compactor Layout

Once you have assessed your current layout and defined your storage needs, it’s time to design your mobile compactor layout. Here are some tips to keep in mind:

- Group Similar Items: Organize items by category or type to streamline picking and inventory management. This grouping will reduce the time spent searching for items.

- Create Clear Aisles: While mobile compactors eliminate fixed aisles, it’s essential to ensure that there is still adequate space for movement. Design your layout with wide aisles that allow easy access to all storage areas.

- Utilize Vertical Space: Mobile compactors can be stacked to make use of vertical space. Ensure that your layout takes full advantage of the height of your warehouse.

- Incorporate Technology: Consider integrating technology such as inventory management systems to track the items stored in your mobile compactor. This technology can help streamline operations and enhance accuracy.

Step 4: Choose the Right Mobile Compactor Manufacturer

Selecting the right mobile compactor manufacturers is crucial to the success of your warehouse optimization. Here are some factors to consider:

- Experience and Reputation: Look for manufacturers with a proven track record in producing high-quality mobile compactor systems. Research customer reviews and case studies to gauge their reputation.

- Customization Options: Different warehouses have varying storage needs. Choose manufacturers that offer customizable solutions to meet your specific requirements.

- Quality and Durability: Ensure that the materials used in the mobile compactors are durable and capable of handling your inventory’s weight and size.

- After-Sales Support: Reliable manufacturers should provide excellent after-sales support, including installation, maintenance, and repairs.

Step 5: Implement Your Mobile Compactor System

After designing your layout and choosing a reputable manufacturer, it’s time to implement your mobile compactor storage system. Here are some best practices for a successful installation:

- Professional Installation: Consider hiring professionals to install your compactor system. This ensures that everything is set up correctly and safely.

- Training for Staff: Provide training for your employees on how to use the new system effectively. Familiarity with the mobile compactor’s operation will enhance productivity.

- Test the System: Before fully integrating the mobile compactor system into your daily operations, conduct tests to ensure that everything functions as intended. This trial run can help identify and resolve any issues.

Step 6: Continuously Evaluate and Adjust

Optimizing your warehouse layout is an ongoing process. After implementing your mobile compactor storage system, continuously evaluate its performance and make adjustments as needed. Consider factors such as:

- Changes in inventory levels and turnover rates

- Employee feedback on accessibility and workflow

- New product lines or changes in storage needs

Regular evaluations will help you maintain an efficient warehouse layout and adapt to any changes in your business operations.

Conclusion

Optimizing your warehouse layout with a mobile compactor storage system can significantly enhance efficiency, accessibility, and overall productivity. By assessing your current layout, defining your storage needs, designing an effective layout, and partnering with reputable mobile compactor manufacturers, you can create a storage solution that meets the demands of your business.

As consumer expectations continue to evolve, investing in innovative storage solutions like mobile compactors will be essential for staying competitive in the marketplace. By maximizing your warehouse space and improving inventory management, you can ensure that your business remains agile and responsive to changing market conditions. Embrace the benefits of compactor storage systems today and take the first step toward optimizing your warehouse layout for success.

Post Comment