Magnetic Separator Machine: Efficient Separation for Maximum Purity

Introduction to Magnetic Separator Machine

In various industries, ensuring product purity and material separation is a crucial part of operations. A Magnetic Separator Machine is an essential tool used to remove ferrous contaminants from raw materials, improving efficiency and maintaining product quality. At Mettherm INC, we specialize in offering high-performance Magnetic Separator Machines designed for various industrial applications, including mining, food processing, pharmaceuticals, and recycling.

This article will explore the working principle, types, applications, benefits, and future trends of magnetic separation technology.

Understanding the Magnetic Separator Machine

A Magnetic Separator Machine works by attracting and separating magnetic materials from non-magnetic substances. These machines are widely used to extract iron, steel, and other ferromagnetic materials from bulk materials, ensuring a contamination-free production process. The efficiency of separation depends on the strength of the magnet, the type of material being processed, and the machine’s design.

Types of Magnetic Separator Machines

There are several types of Magnetic Separator Machines, each designed for specific applications:

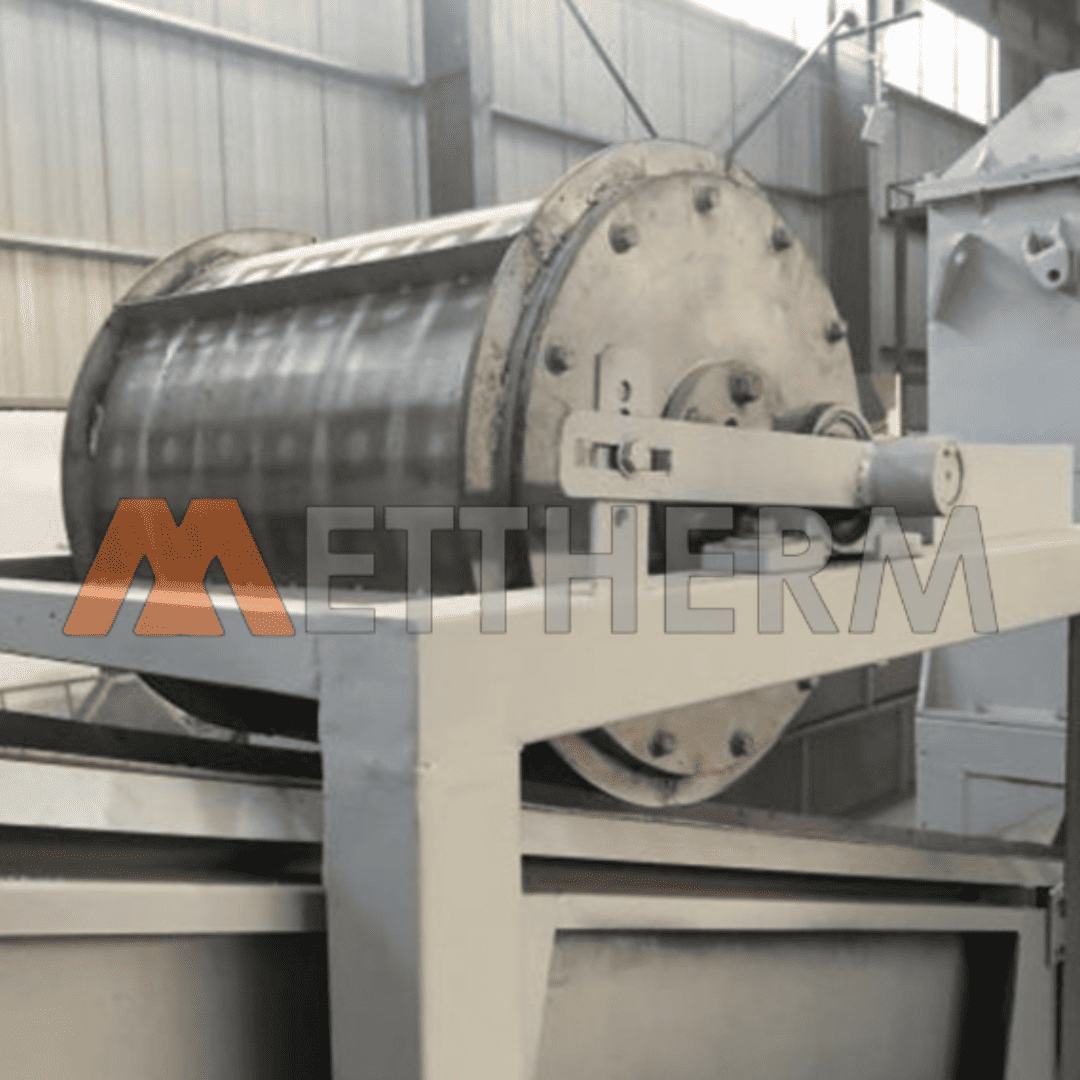

1. Drum Magnetic Separator

Drum separators are one of the most commonly used Magnetic Separator Machines in industries such as mining and recycling. These machines consist of a rotating drum with powerful magnets that attract and separate ferrous materials from non-magnetic materials.

2. Overband Magnetic Separator

An overband Magnetic Separator Machine is used to remove large ferrous contaminants from conveyor belts. It is widely used in recycling and mining industries, ensuring clean material flow by automatically extracting magnetic materials.

3. Eddy Current Separator

Though not purely magnetic, an eddy current separator works alongside Magnetic Separator Machines to remove non-ferrous metals such as aluminum and copper from bulk materials.

4. High-Intensity Magnetic Separator

These Magnetic Separator Machines are used for finer and high-precision separation applications, including pharmaceuticals and food processing, ensuring high purity levels.

5. Wet Magnetic Separator

Used in mineral processing and slurry-based industries, wet Magnetic Separator Machines operate efficiently in separating fine magnetic particles from liquids and slurries.

Working Principle of a Magnetic Separator Machine

A Magnetic Separator Machine operates based on the principle of magnetic attraction. When raw materials pass through the separator, the magnetic field attracts ferromagnetic materials, pulling them away from the main material flow. The separated contaminants are then collected separately, allowing clean material to continue through the production line.

Applications of Magnetic Separator Machines

1. Mining Industry

In the mining sector, Magnetic Separator Machines help remove iron ores, ferrous contaminants, and other unwanted metallic elements from minerals.

2. Food Processing

Food safety is a top priority, and Magnetic Separator Machines play a key role in removing metal contaminants from grains, spices, dairy, and other food products.

3. Pharmaceutical Industry

High-precision Magnetic Separator Machines are used in pharmaceuticals to eliminate tiny metal contaminants from powders, liquids, and raw materials.

4. Recycling Industry

Magnetic separators contribute to efficient recycling by extracting ferrous metals from waste streams, making materials like plastic, paper, and glass reusable.

5. Ceramic and Glass Industry

The ceramic industry uses Magnetic Separator Machines to remove iron particles from clay, ensuring high-quality finished products.

Benefits of Using a Magnetic Separator Machine

Investing in a Magnetic Separator Machine from Mettherm INC offers numerous advantages:

- Enhanced Product Purity: Removes unwanted ferrous materials, ensuring contamination-free production.

- Improved Operational Efficiency: Reduces downtime caused by metal contamination.

- Cost Savings: Decreases wear and tear on machinery by eliminating metal debris.

- Eco-Friendly Solution: Promotes recycling and minimizes industrial waste.

- Versatile Applications: Suitable for various industries, from food processing to mining.

How to Choose the Right Magnetic Separator Machine

Selecting the best Magnetic Separator Machine depends on several factors:

- Material Type: The nature of the material being processed determines the magnet strength required.

- Separation Requirement: Precision levels and particle sizes influence the choice of separator.

- Processing Capacity: The volume of materials processed daily affects the machine selection.

- Operating Conditions: Environmental factors such as temperature and humidity play a role in performance.

At Mettherm INC, we offer expert consultation to help you choose the ideal Magnetic Separator Machine for your needs.

Future Trends in Magnetic Separator Machines

With advancements in technology, Magnetic Separator Machines are evolving to become more efficient and user-friendly. Some emerging trends include:

- Automation & Smart Controls: AI and IoT integration allow for real-time monitoring and performance optimization.

- Stronger Magnetic Fields: New materials and innovations are increasing magnetic separation efficiency.

- Eco-Friendly Designs: Sustainable models consume less energy and reduce environmental impact.

- Compact & Portable Units: Mobile Magnetic Separator Machines provide flexibility for on-site operations.

Why Choose Mettherm INC for Magnetic Separator Machines?

Mettherm INC is a leading provider of high-quality Magnetic Separator Machines, known for durability, efficiency, and precision. Our solutions are customized to meet industrial needs, ensuring top-tier performance. With a commitment to innovation and sustainability, we continue to deliver the best magnetic separation technology to businesses worldwide.

Conclusion

A Magnetic Separator Machine is an essential tool for industries that require efficient separation of ferrous materials from raw materials. With various types available, businesses can choose the right separator based on their specific needs. As technology advances, Magnetic Separator Machines are becoming more efficient, eco-friendly, and user-friendly. At Mettherm INC, we remain committed to providing top-quality magnetic separation solutions that enhance productivity and sustainability.

If you are interested in reading more guest posts like this, you can visit. Freshvoicehub

Post Comment