Lithium Recycling Process: A Sustainable Solution for Recovering Lithium Efficiently

Introduction to the Lithium Recycling Process

Lithium is a critical component in modern technologies, powering everything from electric vehicles to renewable energy storage systems. However, the increasing demand for lithium has led to significant environmental and economic concerns. The Lithium Recycling Process has emerged as a sustainable solution to recover lithium efficiently, reducing dependence on mining and minimizing environmental impact. In this guest post, we will explore the importance of lithium recycling, the steps involved in the recycling process, and how Mettherm INC contributes to sustainable lithium recovery.

Importance of Lithium Recycling

The rapid expansion of lithium-ion battery usage in electric vehicles, mobile devices, and energy storage systems has raised concerns about resource depletion and waste management. The Lithium Recycling Process addresses these challenges by:

- Reducing the need for new lithium mining, which is resource-intensive and environmentally damaging.

- Minimizing landfill waste and preventing hazardous materials from polluting ecosystems.

- Ensuring a stable supply of lithium for future technological advancements.

- Lowering the overall carbon footprint associated with battery production.

Steps in the Lithium Recycling Process

The Lithium Recycling Process involves several crucial steps that ensure efficient recovery and reuse of lithium. These steps include:

1. Collection and Sorting

Used lithium-ion batteries are collected from various sources such as electric vehicles, consumer electronics, and industrial applications. These batteries are then sorted based on chemistry, size, and condition to determine the appropriate recycling method.

2. Discharging and Dismantling

Before processing, batteries must be fully discharged to prevent safety hazards. After discharging, they are dismantled to separate different components such as lithium, cobalt, nickel, and aluminum.

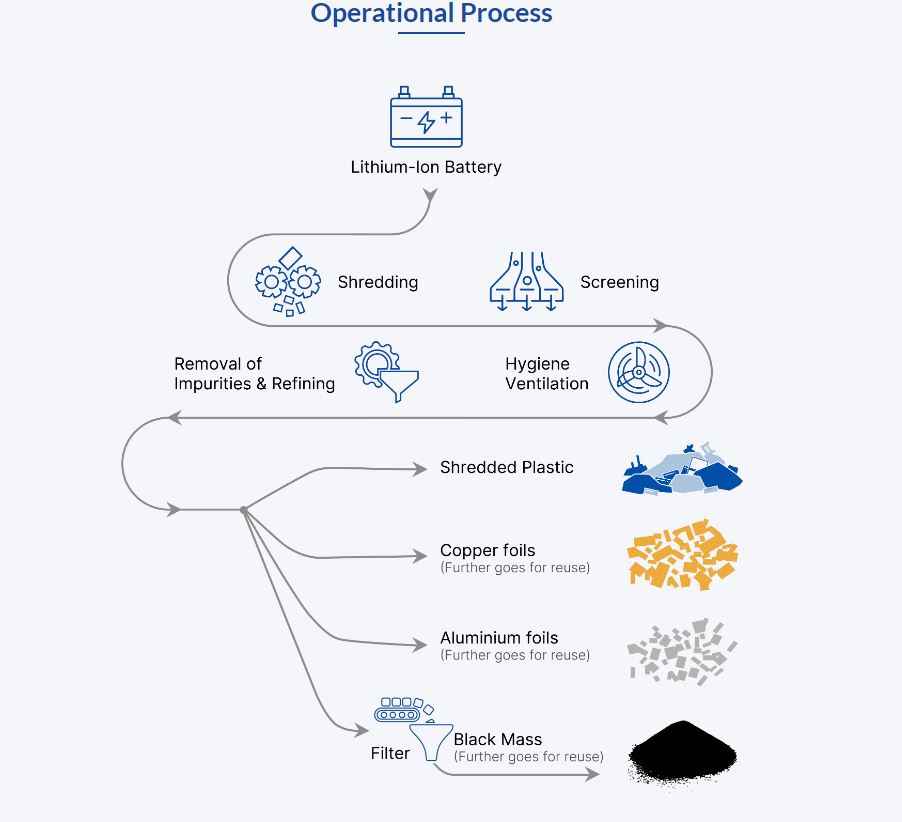

3. Mechanical Processing

Mechanical processes like shredding and crushing help break down battery components into smaller particles. This step facilitates the separation of valuable metals from unwanted materials.

4. Hydrometallurgical Processing

Hydrometallurgical techniques involve chemical leaching to extract lithium and other valuable metals from the battery materials. This method is known for its high recovery efficiency and lower environmental impact compared to traditional smelting processes.

5. Purification and Precipitation

The extracted lithium undergoes purification to remove impurities. Precipitation methods are used to convert lithium into lithium carbonate or lithium hydroxide, which can be reused in battery manufacturing.

6. Reuse and Reproduction

Once purified, recycled lithium is reintroduced into the supply chain for the production of new lithium-ion batteries. This closed-loop recycling system ensures sustainable and efficient use of resources.

Challenges in the Lithium Recycling Process

Despite its numerous benefits, the Lithium Recycling Process faces several challenges, including:

- High Cost: The cost of recycling lithium remains higher than traditional mining due to complex recovery procedures.

- Limited Infrastructure: Many regions lack the necessary facilities and expertise to implement large-scale lithium recycling.

- Battery Variability: Different battery chemistries require different recycling approaches, making standardization difficult.

- Environmental Concerns: Some recycling methods generate toxic byproducts, requiring advanced waste management solutions.

Future of Lithium Recycling

With advancements in technology and increasing government support for sustainable initiatives, the Lithium Recycling Process is expected to become more efficient and cost-effective. Innovations such as direct recycling methods, AI-driven sorting, and improved hydrometallurgical techniques will further enhance lithium recovery rates.

Mettherm INC: Leading the Way in Lithium Recycling

As a pioneer in sustainable recycling solutions, Mettherm INC is committed to advancing the Lithium Recycling Process through cutting-edge technology and eco-friendly practices. Our expertise in battery recycling ensures maximum lithium recovery with minimal environmental impact. By collaborating with industry leaders, policymakers, and researchers, we strive to create a circular economy for lithium and contribute to a greener future.

Conclusion

The Lithium Recycling Process is an essential step toward a sustainable and resource-efficient future. By reducing dependency on mining and minimizing environmental damage, lithium recycling plays a crucial role in promoting a circular economy. Companies like Mettherm INC are at the forefront of this transformation, developing innovative solutions for efficient lithium recovery. With continuous advancements and industry-wide support, the future of lithium recycling looks promising, paving the way for a cleaner and more sustainable world.

If you are interested in reading more guest posts like this, you can visit: freshvoicehub

Post Comment