Hypochlorous Acid Manufacturing Plant Project Report 2025: Key Insights and Strategies

Introduction

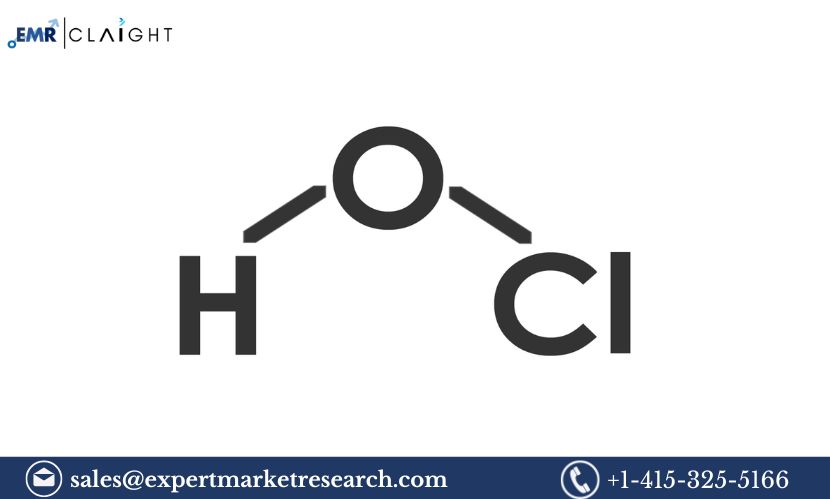

Hypochlorous acid (HOCl) is a powerful oxidizing agent that has broad applications in various industries, including healthcare, sanitation, and food processing. It is used for disinfecting surfaces, sanitizing water, and treating wounds due to its strong antimicrobial properties. The increasing need for effective disinfectants and sanitation solutions, particularly in the wake of global health concerns, has spurred demand for hypochlorous acid. Establishing a Hypochlorous Acid Manufacturing Plant can be a lucrative business opportunity for entrepreneurs looking to capitalize on the growing global emphasis on hygiene and safety. This Hypochlorous Acid Manufacturing Plant Project Report offers a comprehensive analysis of the production process, market demand, regulatory considerations, and financial aspects of setting up a successful manufacturing facility.

Market Overview and Trends

Growing Demand for Hypochlorous Acid

The demand for hypochlorous acid has surged across various sectors due to its highly effective disinfecting, sterilizing, and sanitizing properties. Some key drivers of its demand include:

- Healthcare and Medical Applications: Hypochlorous acid is used for wound cleaning, infection control in hospitals, and as a disinfectant for medical equipment. It is preferred due to its non-toxic and non-irritating properties compared to other chemicals like bleach.

- Water Treatment: HOCl is an effective disinfectant for treating drinking water and wastewater. It helps in killing harmful microorganisms, making it suitable for public health systems.

- Food Industry: Hypochlorous acid is used as a food-grade sanitizer to disinfect food processing equipment and ensure food safety. It is also used for surface sanitization in the packaging industry.

- Agriculture: HOCl is employed in the agricultural industry for sterilizing irrigation water, preventing diseases, and enhancing crop health.

- Personal Care and Cosmetics: The antimicrobial properties of hypochlorous acid are used in skincare products, especially for wound care, acne treatment, and general hygiene.

Get a Free Sample Report with Table of Contents@

Industry Trends

- Increased Focus on Hygiene and Sanitation: The COVID-19 pandemic has heightened global awareness of hygiene and the importance of effective disinfectants. This trend is expected to continue driving the demand for hypochlorous acid.

- Sustainable Solutions: There is a growing shift toward eco-friendly disinfectants and sanitizers. Hypochlorous acid is gaining popularity due to its environmentally friendly nature and the fact that it breaks down into harmless substances like water and salt after use.

- Rising Health and Wellness Consciousness: Consumers are becoming more health-conscious, preferring natural and non-toxic products for personal care, healthcare, and food safety. Hypochlorous acid fits these preferences due to its safe, non-toxic properties.

Regional Demand for Hypochlorous Acid

- North America and Europe: The demand for hypochlorous acid is high in developed regions due to strong healthcare infrastructure, stringent hygiene regulations, and widespread adoption of advanced sanitation techniques.

- Asia-Pacific: Countries like China and India are experiencing rapid industrialization and urbanization, leading to an increased need for sanitation and disinfecting products, including hypochlorous acid.

- Latin America and Middle East: As awareness of hygiene and disease prevention grows, countries in these regions are beginning to adopt hypochlorous acid in water treatment, agriculture, and healthcare.

Manufacturing Process

The production of hypochlorous acid involves the electrolysis of saltwater or sodium chloride solution. Below is a breakdown of the typical manufacturing process:

1. Raw Materials

The key raw material used in the production of hypochlorous acid is sodium chloride (NaCl), which is commonly available in the form of table salt. Additionally, water (preferably deionized) and electricity are required for the electrolysis process.

2. Electrolysis Process

The core method for producing hypochlorous acid is the electrolysis of saltwater. This process involves passing an electric current through a sodium chloride solution. The electrolysis reaction breaks down the sodium chloride into various chemical components, including:

- Sodium hydroxide (NaOH)

- Chlorine gas (Cl₂)

- Hypochlorous acid (HOCl)

The electrolysis process typically takes place in a diaphragm cell or a membrane cell reactor, which separates the different by-products of electrolysis. The primary objective is to produce hypochlorous acid, which is then concentrated and purified.

3. Separation and Purification

After the electrolysis process, the hypochlorous acid produced is in a dilute form, and it needs to be separated and purified. The chlorine gas is removed, and the sodium hydroxide is neutralized to obtain pure hypochlorous acid. The final product is a clear, colorless liquid with a slightly acidic pH.

4. Concentration

Hypochlorous acid is typically produced in a diluted form (around 0.5% to 1% concentration) and may need to be concentrated to meet specific customer requirements. This can be done by evaporating water or using chemical concentration methods to achieve the desired concentration.

5. Packaging and Storage

Once the hypochlorous acid is prepared and concentrated, it is packaged in suitable containers, such as plastic drums or bottles, and stored in a cool, dry environment. Special precautions are taken to ensure the stability of the acid and avoid degradation due to exposure to light and heat.

Equipment and Technology

To set up a Hypochlorous Acid Manufacturing Plant, specialized equipment is necessary for the electrolysis process, concentration, and packaging. Some essential equipment includes:

- Electrolytic Cells: These cells are designed for the electrolysis of saltwater and the production of hypochlorous acid. They can either be diaphragm-based or membrane-based, depending on the scale of production.

- Cooling Systems: Since electrolysis generates heat, efficient cooling systems are necessary to maintain optimal operating temperatures in the cells.

- Chemical Neutralization Units: After electrolysis, chemical neutralization units are used to remove excess sodium hydroxide and produce pure hypochlorous acid.

- Concentration Units: To achieve the desired concentration of hypochlorous acid, evaporation or filtration systems are used.

- Storage Tanks and Packaging Equipment: Specialized tanks are used for storing hypochlorous acid before it is packaged. Automated packaging machines ensure that the product is packaged efficiently and safely.

Emerging Technologies in Hypochlorous Acid Production

- Energy-Efficient Electrolysis: Research is ongoing to improve the energy efficiency of the electrolysis process, reducing operational costs.

- Electrochemical Reactors: Advanced electrochemical reactors can improve the yield of hypochlorous acid, enhance purity, and minimize the production of unwanted by-products.

- Automation and Control Systems: Automation technology helps optimize the manufacturing process, ensuring consistent product quality and reducing human error.

Regulatory Compliance and Certifications

Regulatory Standards

The production of hypochlorous acid is subject to various regulatory standards to ensure product safety and quality:

- FDA and EPA Regulations: For hypochlorous acid used in food safety, healthcare, and cosmetics, compliance with FDA and EPA guidelines is necessary. These agencies regulate the safe use and labeling of chemicals in consumer products.

- ISO Certifications: Manufacturers can obtain certifications such as ISO 9001 for quality management and ISO 14001 for environmental management to demonstrate their commitment to producing high-quality products while maintaining environmental responsibility.

- CE Marking: In Europe, hypochlorous acid products intended for medical and food-related uses may require CE marking, indicating compliance with EU health and safety standards.

Environmental Considerations

Hypochlorous acid production can have environmental impacts, particularly concerning the use of electricity and water in the electrolysis process. Manufacturers are encouraged to adopt sustainable practices, such as:

- Water Recycling: Reusing water in the electrolysis process to minimize consumption and waste.

- Energy-Efficient Production: Utilizing renewable energy sources, such as solar or wind power, to reduce the carbon footprint of the manufacturing plant.

- Waste Management: Properly disposing of or recycling by-products and chemical waste from the production process.

Financial Considerations

Capital Investment

Setting up a Hypochlorous Acid Manufacturing Plant involves significant capital investment. Key expenditures include:

- Land and Infrastructure: Purchasing land and building the plant infrastructure.

- Machinery and Equipment: Purchasing electrolytic cells, neutralization units, storage tanks, and packaging equipment.

- Raw Materials: Sourcing sodium chloride and other chemicals required for the electrolysis process.

Operational Costs

Ongoing operational expenses include:

- Raw Material Costs: The cost of sodium chloride and water.

- Energy Costs: Electrolysis is energy-intensive, so electricity costs are a significant portion of the operational budget.

- Labor Costs: Wages for workers involved in the production, quality control, and packaging processes.

- Maintenance and Repairs: Regular maintenance of equipment to ensure smooth operation.

Revenue Potential

The revenue potential for a Hypochlorous Acid Manufacturing Plant is substantial, driven by the increasing demand for sanitizing products in various industries. Profitability depends on factors such as production capacity, product quality, and effective distribution channels.

Supply Chain and Distribution

The supply chain for hypochlorous acid involves:

- Raw Material Sourcing: Securing reliable suppliers of sodium chloride.

- Manufacturing and Quality Control: Ensuring consistent product quality through rigorous testing.

- Packaging and Distribution: Packaging the final product in bulk or smaller quantities for distribution to industries such as healthcare, food processing, and agriculture.

Media Contact

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Post Comment