How to Solve the Common Challenges in Precast Panel Detailing

Precast construction has become a preferred method in modern building projects due to its speed, efficiency, and sustainability. However, the success of any precast project hinges on one crucial aspect: precast panel detailing. While the advantages of using precast elements are clear, the process of detailing them comes with its own set of challenges. Missteps in this stage can lead to delays, cost overruns, and structural issues.

In this blog, we highlight some of the most common challenges in precast detailing — and practical ways to solve them using smart planning, the right expertise, and effective collaboration.

1. Incomplete or Inaccurate Inputs

One of the biggest issues a precast detailer faces is receiving incomplete architectural or engineering drawings. Missing dimensions, unclear specifications, or changes during design development can create confusion and rework during the detailing process.

Solution:

Establish early and consistent coordination between architects, engineers, and precast detailers. Make sure to use updated and approved design documents as the base for all precast detailing work. Regular meetings and design reviews can also help clarify expectations and minimise errors.

2. Coordination Issues Across Disciplines

Precast panel detailing doesn’t exist in a vacuum. It must align with architectural aesthetics, structural loads, MEP penetrations, and site conditions. Lack of coordination between disciplines can lead to clashes, misalignments, or rework on-site.

Solution:

Adopt Building Information Modeling (BIM) to enable better integration of structural engineering services, MEP systems, and architectural elements. BIM allows all stakeholders to identify clashes early and resolve them in the digital environment before fabrication begins

3. Complex Panel Geometry

Modern buildings often feature complex shapes, curved surfaces, or angled connections. These architectural elements may be visually appealing, but they pose serious challenges for precast detailing services. Irregular forms increase the difficulty of creating accurate shop drawings and connections.

Solution:

Invest in experienced precast detailers familiar with advanced 3D modelling tools. Break complex shapes into simpler components wherever possible, and consult with structural engineers to ensure stability and practicality in panel design. Prefabrication trials or mock-ups can also help test feasibility.

4. Unclear Load Paths and Connection Details

A precast concrete detail must account for how panels connect to each other and transfer loads to the foundation. Poorly designed or vague connections can lead to instability, cracking, or difficulty during installation.

Solution:

Involve structural engineering services from the beginning of the detailing process. Detailed connection designs, including bearing lengths, dowel bars, and inserts, should be clearly specified and verified against load calculations. Each precast concrete detail must address not only vertical loads but also lateral and thermal forces.

5. Tight Construction Schedules

Construction timelines are often compressed, putting pressure on the detailing team to deliver quickly. However, rushing through precast detailing can lead to costly errors, missed coordination, or fabrication delays.

Solution:

Use phased submissions of precast detailing packages to begin fabrication while other sections are still being detailed. Employ skilled precast detailing services that can scale output based on project timelines. Automation tools and libraries of standard details can also speed up the process without compromising quality.

6. Limited Tolerance for Site Adjustments

Precast panels are built offsite and delivered ready for installation. This leaves little room for last-minute modifications if site measurements differ from the plan. Even small inaccuracies can cause misalignment or require rework.

Solution:

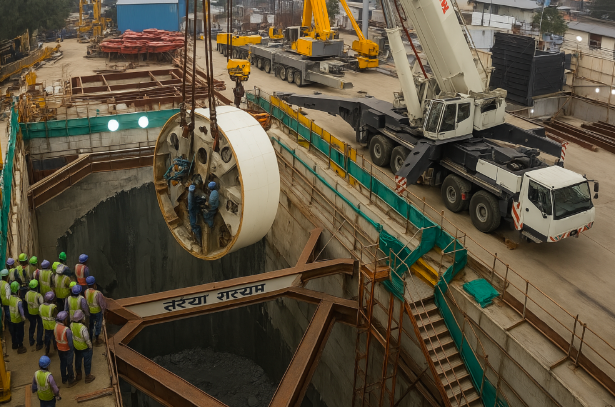

Ensure that a site survey is completed and aligned with the precast detailing phase. Include realistic erection tolerances in every precast panel detailing document. Collaborate with the installation team to plan crane access, lifting points, and site logistics, reducing the risk of surprises during installation.

7. Variation in Local Standards and Codes

Precast detailing must comply with local building codes, which may vary from region to region. For international projects, misunderstanding local requirements can result in non-compliant designs and costly revisions.

Solution:

Work with precast detailers who are experienced in local code compliance. Ensure that structural engineering services are integrated early in the detailing process to double-check compliance with local safety and performance regulations.

8. Communication Gaps Between Teams

Precast projects often involve multiple stakeholders spread across different time zones and companies. Communication delays or unclear instructions can slow progress or lead to mistakes in the detailing process.

Solution:

Establish a central communication platform where all stakeholders can track progress, raise queries, and review drawings in real time. Clear documentation and change logs are also essential to maintain transparency and avoid confusion.

Final Thoughts

Precast panel detailing is a critical link between design and construction. Done correctly, it ensures a smooth flow from design intent to final assembly. But challenges like coordination issues, complex geometry, or rushed schedules can derail even the best-planned projects.

By engaging experienced precast detailing services and integrating structural engineering services from the outset, these challenges can be anticipated and resolved. The expertise of a skilled precast detailer, combined with smart planning and collaboration, leads to more accurate designs, safer installations, and better project outcomes.

Whether you’re working on a commercial high-rise or infrastructure project, addressing these detailing challenges early can save both time and money — and ensure long-term structural performance.