How RS-485 IoT Gateways Enhance Industrial IoT Applications

The Industrial Internet of Things (IIoT) has revolutionized industries by enabling machines, sensors, and devices to communicate and share data in real-time. This shift to smart automation has led to significant improvements in efficiency, productivity, and operational decision-making. A key component in making IIoT systems work is the IoT gateway, which acts as a bridge between industrial devices and higher-level network systems like cloud platforms or enterprise management software.

Communication protocols, such as RS-485, play an essential role in ensuring reliable data transmission across various devices. These protocols define the standards for physical layer communication and data formatting, ensuring that industrial systems can work together despite their inherent differences in operation and design.

Importance of IoT Gateways in Industrial Applications

An IoT Gateway serves as a pivotal node within an industrial network, facilitating communication between IoT devices, sensors, and the central system. Without a robust gateway solution, integrating multiple devices across large geographical areas, or interfacing with legacy systems, would be nearly impossible. RS-485 IoT Gateways specifically address the communication demands of industrial environments, requiring high-speed and long-distance data transmission.

What is an RS-485 IoT Gateway?

RS-485 (Recommended Standard 485) is a differential bus standard that allows for the reliable transmission of data over long distances. RS-485 plays a vital role in industrial communication networks because it offers robustness and supports multiple devices on the same bus. Unlike RS-232, which limits communication to point-to-point connections, RS-485 enables multi-drop configurations, connecting up to 32 devices on a single network.

RS-485 operates over twisted pair cables, which help reduce electromagnetic interference (EMI), making it ideal for environments where electrical noise could degrade communication quality. It also offers significant advantages in terms of distance—up to 4,000 feet (1,200 meters) in some cases—without losing data integrity.

Key Features of RS-485 IoT Gateways

An RS-485 IoT Gateway typically features the following:

- Multi-protocol Support: These gateways can handle multiple industrial protocols (Modbus RTU, BACnet, etc.), making them versatile for different applications.

- Long-Distance Communication: Capable of transmitting data over significant distances (up to 4,000 feet).

- Multi-Device Connectivity: Supports multiple devices through RS-485 bus architecture.

- Data Aggregation: Collects and consolidates data from various industrial devices before forwarding it to higher-level systems like SCADA or cloud platforms.

How RS-485 Works in IoT Environments

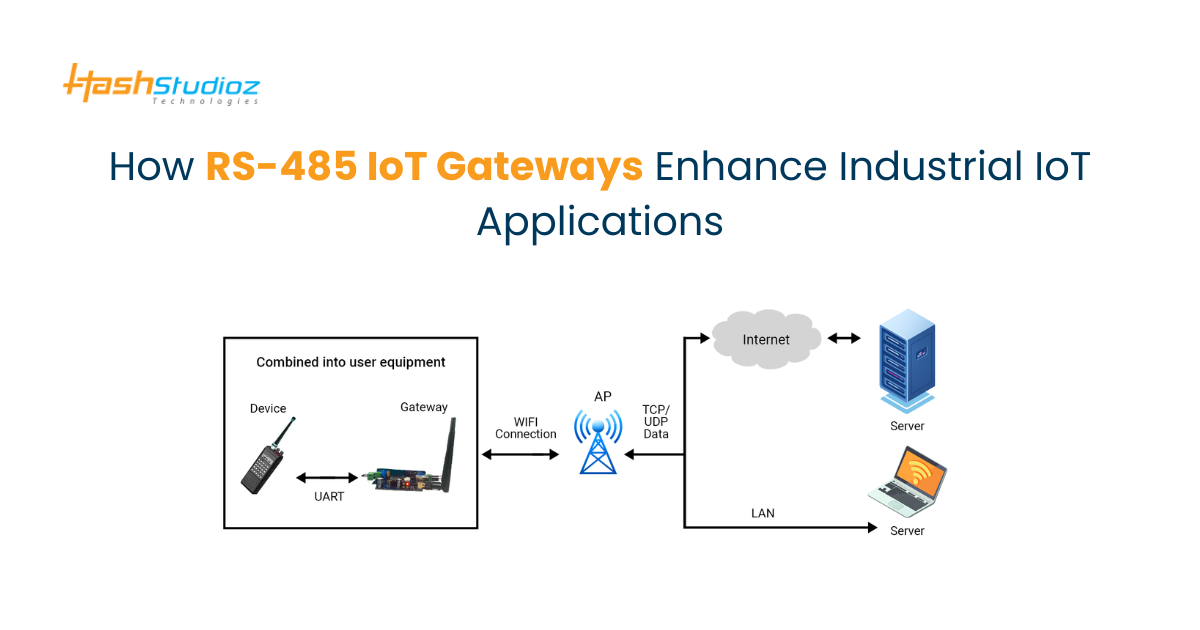

RS-485 IoT Gateways are designed to seamlessly convert industrial data from RS-485 devices into a format that can be processed by modern IoT systems. The gateway acts as an intermediary between legacy equipment and cloud platforms or other advanced technologies, enabling real-time data flow and system integration.

Why Choose RS-485 IoT Gateways for Industrial Applications?

Reliable Communication for Industrial Systems

In industrial environments, communication reliability is critical. RS-485 IoT Gateways ensure that data can be transmitted reliably even in electrically noisy environments, such as factories or power plants, where electromagnetic interference could disrupt data flow. This robust communication ensures continuous operations without interruptions.

Long-Distance Data Transmission Capabilities

RS-485’s ability to transmit data over long distances without degradation is another reason why these gateways are ideal for industrial applications. Factories or industrial setups often span large areas, requiring reliable long-distance data transmission for monitoring and control systems. RS-485 IoT Gateways meet this requirement by supporting up to 4,000 feet of data transmission.

Noise Immunity and Robustness

Electromagnetic noise can be detrimental to industrial communications. RS-485 IoT Gateways are designed to handle these challenges by using differential signaling, which allows the transmission of signals over twisted-pair cables. This design significantly reduces the impact of EMI and ensures stable communication even in challenging industrial environments.

Cost-Effective Solution for Large-Scale Deployments

RS-485 IoT Gateways are cost-effective due to their ability to support a large number of devices with minimal cabling. The ability to connect up to 32 devices on a single bus simplifies installations and reduces the overall cost of the IoT network, making it an attractive option for large-scale industrial deployments.

How RS-485 IoT Gateways Integrate with Industrial IoT Applications

Connecting Legacy Systems to Modern IoT Frameworks

Many industries rely on legacy equipment and systems that are essential to their operations. RS-485 IoT Gateways provide an essential function by bridging the gap between these older systems and modern IoT platforms. This integration enables businesses to adopt IoT capabilities without completely replacing their existing infrastructure, thus extending the lifespan of their legacy systems.

Seamless Data Transmission for Real-Time Monitoring

RS-485 IoT Gateways play a critical role in facilitating real-time data transfer across the industrial network. By converting legacy communication formats into digital signals that modern systems can process, these gateways enable real-time monitoring of critical assets, sensors, and devices. This allows for better decision-making and more efficient resource management.

Enabling Remote Control and Automation

Automation and remote control are key benefits of integrating IoT into industrial applications. RS-485 IoT Gateways facilitate these processes by enabling the remote collection of data and the transmission of control commands across industrial networks. This is particularly useful for managing systems like HVAC, power generation, and production lines.

RS-485 IoT Gateways and Industrial IoT Solutions

Integrating with SCADA Systems and PLCs

RS-485 IoT Gateways are essential in connecting Supervisory Control and Data Acquisition (SCADA) systems and Programmable Logic Controllers (PLCs) to the larger IoT ecosystem. These systems are fundamental in managing complex industrial processes, and RS-485 IoT Gateways ensure that data from these systems can be aggregated, analyzed, and used to optimize performance.

Use Cases in Smart Manufacturing

RS-485 IoT Gateways are widely used in smart manufacturing environments, where they facilitate communication between sensors, machines, and control systems. By enabling continuous data flow and analytics, they help improve production efficiency, reduce waste, and enhance predictive maintenance practices.

Application in Environmental Monitoring

In industries where environmental conditions are critical, such as oil and gas or chemical plants, RS-485 IoT Gateways are used to integrate environmental sensors with central monitoring systems. These gateways ensure real-time data transmission from remote locations to centralized systems, enabling better control over environmental parameters like temperature, pressure, and gas levels.

Enhancing Predictive Maintenance with RS-485 IoT Gateways

RS-485 IoT Gateways support predictive maintenance by transmitting real-time data from industrial machines and equipment. With this data, predictive analytics can be performed to anticipate failures, reducing downtime and improving operational efficiency. This is particularly valuable in industries with high maintenance costs and complex machinery.

Key Benefits of RS-485 IoT Gateways in Industrial IoT

Scalability and Flexibility

RS-485 IoT Gateways are highly scalable, making them suitable for small setups as well as large industrial networks. With the ability to connect multiple devices on the same bus, they offer flexibility to expand the network as needed without significant additional costs.

Improved System Reliability and Uptime

By ensuring stable and continuous communication between devices, RS-485 IoT Gateways improve system reliability. In industrial environments where downtime can be costly, the gateway ensures that critical systems stay online, enhancing overall uptime and operational efficiency.

Enhanced Security Features

Security is a major concern for industrial networks, especially with the increasing threats posed by cyberattacks. RS-485 IoT Gateways come with built-in security features like encryption and secure access control to protect data integrity and prevent unauthorized access.

Reducing Downtime and Operational Costs

By enabling predictive maintenance and remote monitoring, RS-485 IoT Gateways help reduce the likelihood of unexpected downtime. This, in turn, leads to cost savings in maintenance and repairs, as well as improved resource management across the entire industrial operation.

RS-485 IoT Gateway Implementation Best Practices

Proper Placement and Network Design

When deploying RS-485 IoT Gateways, it’s essential to consider network topology and device placement. This ensures that signal integrity is maintained and that all devices are connected in the most efficient manner possible.

Choosing the Right RS-485 IoT Gateway for Your Industry

Not all RS-485 IoT Gateways are created equal. Depending on the industry and the specific requirements of the application, businesses must carefully choose a gateway that supports the right protocols, communication speeds, and connectivity options.

Ensuring Data Security and Privacy

Security should be a top priority when implementing RS-485 IoT Gateways. This includes using encryption, secure user authentication, and regularly updating the gateway’s firmware to protect against vulnerabilities.

Troubleshooting and Maintaining RS-485 IoT Gateways

Like any industrial equipment, RS-485 IoT Gateways require regular maintenance and troubleshooting. Regular checks on device connections, network performance, and firmware updates can prevent issues before they disrupt operations.

Real-World Examples of RS-485 IoT Gateway Applications

1: Smart Manufacturing Facility

A smart manufacturing facility used RS-485 IoT Gateways to integrate legacy machines with a new IoT-based monitoring system. The gateway facilitated real-time data transmission from sensors on the production line to the cloud, enabling predictive maintenance and reducing production downtime.

2: Automated Energy Monitoring System

An energy provider deployed RS-485 IoT Gateways to connect energy meters across a wide geographical area to a central monitoring system. The gateway allowed for real-time data collection and analytics, which helped optimize energy usage and reduce operational costs.

3: Environmental Data Collection in Remote Locations

In an environmental monitoring project, engineers used RS-485 IoT Gateways to connect remote weather sensors to a central system. The gateways reliably transmitted data from sensors in harsh and remote environments for analysis and decision-making.

Conclusion

RS-485 IoT Gateways play a crucial role in enhancing industrial IoT applications by providing reliable, long-distance, and noise-resistant data transmission. These gateways not only facilitate seamless integration of legacy systems with modern IoT infrastructures but also enable real-time monitoring, predictive maintenance, and remote control. By leveraging the capabilities of RS-485 IoT Gateways, industries can improve their operational efficiency, reduce downtime, and make more informed decisions.

FAQs

What is the main advantage of using RS-485 IoT Gateways in industrial applications?

RS-485 IoT Gateways provide reliable, long-distance communication, noise immunity, and cost-effective scalability for industrial networks.

How do RS-485 IoT Gateways ensure reliability in noisy environments?

RS-485 IoT Gateways use differential signaling, which minimizes the impact of electromagnetic interference (EMI), ensuring stable communication in noisy environments.

Can RS-485 IoT Gateways be used to connect legacy equipment to modern IoT systems?

Yes, RS-485 IoT Gateways can bridge the gap between legacy systems and modern IoT platforms, allowing for integration without replacing older equipment.

What are the common challenges when deploying RS-485 IoT Gateways?

Challenges include proper network design, ensuring signal integrity over long distances, and maintaining security protocols.

Post Comment