How Power Transmission Parts Impact the Efficiency of Industrial Machinery

In the world of industrial machinery, efficiency is paramount. Every component of a system, from motors to gears, plays a crucial role in ensuring smooth operation and maximizing productivity. Among these components, power transmission parts hold a significant position. These parts transfer mechanical energy from one component to another, ensuring that machines function properly and without unnecessary delays. One such vital part of power transmission systems is the sprocket roller chain. The performance of these parts directly affects the overall efficiency of industrial machinery.

At Voodoo Sprockets, we understand the importance of selecting the right power transmission parts. Our focus is on providing high-quality sprockets that optimize the efficiency of your machinery, ensuring smooth operation and extending the lifespan of your equipment. This blog will explore how power transmission parts, particularly sprockets and roller chains, impact the efficiency of industrial machinery and why choosing the right parts is critical to success.

Understanding Power Transmission Parts

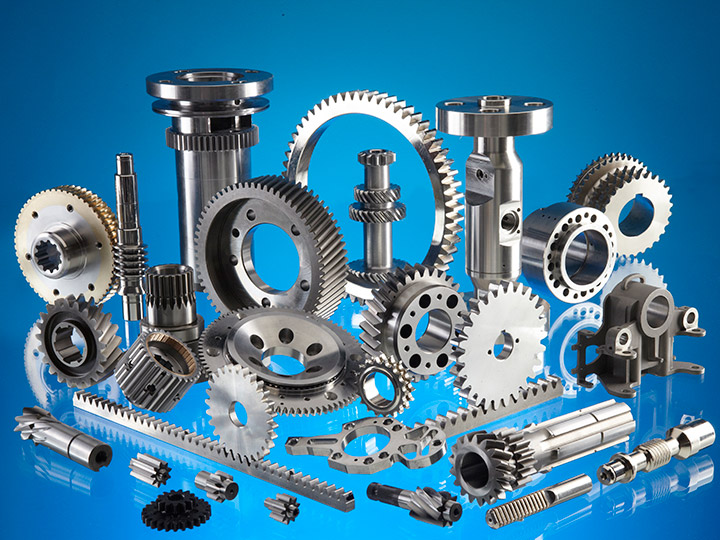

Power transmission parts are the backbone of many industrial machines, allowing energy to flow from one component to another. These parts work in unison to ensure that the movement and force generated by a motor or engine are efficiently transferred to the rest of the machinery. Examples of power transmission parts include gears, belts, pulleys, couplings, and sprocket roller chains.

A sprocket roller chain system, for example, is commonly used to transfer rotational force between two shafts. This system is made up of sprockets (the toothed wheels) and a roller chain (the links that connect the sprockets). The efficiency of these components is directly related to the machine’s overall performance. If the sprocket roller chain is not properly selected or maintained, it can lead to excessive wear, energy loss, or even complete failure of the machinery.

For industrial machines that operate in high-demand environments, the quality and design of the power transmission parts are critical. A well-designed sprocket and roller chain system can significantly reduce friction, minimize energy loss, and increase the overall operational efficiency of the machinery.

The Role of Power Transmission Parts in Efficiency

The efficiency of any machine is determined by how effectively its energy is transferred and converted. Power transmission parts play a central role in this energy transfer. When these parts are of high quality and are properly maintained, they ensure smooth power flow with minimal energy loss. Let’s dive deeper into the specific ways in which power transmission parts influence the efficiency of industrial machinery:

Reduction of Energy Loss:

High-quality sprockets and roller chains are designed to minimize friction between moving parts. Less friction means less energy is lost in the form of heat. With less energy loss, machines run more efficiently, reducing operational costs.

Enhanced Durability:

Durable power transmission parts like Voodoo Sprockets are built to withstand the rigors of industrial environments. Machines that operate with durable parts experience fewer breakdowns and require less frequent maintenance. This reduces downtime and increases the productivity of the operation.

Optimal Performance:

Power transmission systems are designed to work with specific machines. When the right sprocket and roller chain are selected, the machine can perform at its peak efficiency. If the wrong parts are used, the machine may struggle to function as intended, leading to decreased productivity and higher energy consumption.

Noise Reduction:

Industrial machinery often operates in noisy environments, but well-designed power transmission parts can help reduce the noise produced. A properly maintained sprocket roller chain system, for example, will reduce vibrations and noise, creating a more pleasant working environment and less wear on the machinery.

Improved Safety:

When Voodoo Sprockets and other high-quality power transmission parts are used, the risk of system failures is greatly reduced. Well-maintained parts prevent unexpected breakdowns that could pose safety hazards to workers and damage to expensive machinery.

Why Choosing the Right Sprocket Roller Chain Matters

One of the most critical power transmission parts in any industrial machine is the sprocket roller chain. This system is responsible for transferring rotational motion between two shafts, and its performance directly impacts the efficiency of the machine. Choosing the right sprocket and roller chain is essential for the following reasons:

Proper Sizing:

The size of the sprocket and roller chain should match the machine’s requirements. An oversized or undersized sprocket can lead to inefficient power transfer, excessive wear, and even system failure. The right size ensures that the system runs efficiently, minimizing energy loss.

Material Selection:

The material used to manufacture sprockets and roller chains is crucial for their durability and performance. Materials such as high-carbon steel, stainless steel, or alloy steels are commonly used for industrial applications due to their strength and resistance to wear. Selecting the appropriate material will ensure the parts can handle the stresses of industrial operations.

Load Capacity:

Industrial machines often deal with varying loads, and a sprocket roller chain system must be capable of handling these loads without failure. A properly selected sprocket roller chain can handle both the peak and sustained loads, ensuring consistent performance and avoiding mechanical failures.

Environmental Factors:

Depending on the environment in which the machinery operates, certain materials and designs may be more suitable. For example, environments with high temperatures or exposure to corrosive elements require parts made from resistant materials to prevent degradation and maintain efficiency.

Maintenance and Adjustments:

Regular maintenance is vital to keep power transmission parts functioning efficiently. Ensuring that the sprocket roller chain is properly lubricated, adjusted, and aligned will reduce wear and prevent performance issues. Voodoo Sprockets and other high-quality brands often provide guidance on proper maintenance schedules to ensure optimal performance.

How Voodoo Sprockets Enhance Industrial Machinery Efficiency

At Voodoo Sprockets, we understand the critical role that power transmission parts play in the efficiency of industrial machinery. Our sprockets are designed with precision to provide reliable and long-lasting performance. Here’s how our sprockets and roller chains contribute to improved machine efficiency:

Precision Engineering:

Our sprockets are designed to meet the specific needs of industrial machines. Each sprocket is engineered with accuracy to ensure that it meshes perfectly with the roller chain, minimizing friction and maximizing efficiency.

High-Quality Materials:

We use high-strength materials that are resistant to wear and tear, ensuring that your power transmission parts last longer. This reduces the need for frequent replacements, cuts down on downtime, and lowers overall maintenance costs.

Customized Solutions:

At Voodoo Sprockets, we offer customized sprockets tailored to your machinery’s specific requirements. By providing the exact specifications, we ensure that your machinery operates at optimal efficiency, with minimal energy loss and maximum productivity.

Cost-Effective Performance:

While high-quality sprockets may have a higher initial cost, their durability and efficiency lead to long-term savings. By reducing energy consumption and increasing the lifespan of other components, our sprockets offer cost-effective solutions in the long run.

Reliability:

Reliability is key in any industrial setting, and our sprockets and roller chains are built to perform under the most demanding conditions. With Voodoo Sprockets, you can trust that your power transmission parts will continue to deliver consistent performance, reducing the risk of unplanned downtime.

The efficiency of industrial machinery is largely determined by the performance of its power transmission parts. High-quality components like Voodoo Sprockets and sprocket roller chains ensure that mechanical energy is transferred smoothly and efficiently throughout the system, resulting in reduced energy loss, increased durability, and enhanced overall performance. Choosing the right power transmission parts is essential for optimizing machinery efficiency and minimizing operational costs. Whether you’re looking to improve the performance of an existing system or build a new one, investing in high-quality sprockets and roller chains from a trusted supplier like Voodoo Sprockets will pay dividends in the form of improved productivity and cost savings.

By understanding the critical role that power transmission parts play, you can make informed decisions that will have a lasting impact on the efficiency of your industrial machinery.

Post Comment