How Molded Pulp Attributes Reduce Carbon Footprints in Packaging

Packaging solutions have undergone significant transformations over the years, with sustainability becoming a central focus. Molded pulp, a renewable material derived from recycled paper and other natural fibers, has emerged as an eco-friendly alternative to traditional packaging options. By understanding the unique molded pulp attributes, businesses can significantly reduce their carbon footprints while contributing to a greener future.

Sustainable Raw Materials: A Foundation for Eco-Friendliness

Molded pulp packaging is primarily made from recycled paper, cardboard, and natural fibers like bamboo or bagasse. These materials are abundantly available and biodegradable, unlike plastics derived from fossil fuels. By utilizing waste products, molded pulp reduces the demand for virgin raw materials, conserving natural resources and decreasing energy consumption during production.

Additionally, the reliance on renewable resources ensures that molded pulp products are not only environmentally friendly but also part of a circular economy. These materials can be recycled or composted at the end of their lifecycle, minimizing landfill waste and reducing greenhouse gas emissions associated with decomposition.

Energy-Efficient Production Processes

The production of molded pulp packaging involves relatively low energy consumption compared to traditional materials like plastic or glass. Using water-based processes to mold and shape the pulp requires significantly less energy than the high temperatures and specialized machinery needed for manufacturing plastics.

Furthermore, many facilities producing molded pulp packaging incorporate renewable energy sources such as solar or wind power into their operations. This approach aligns with sustainability goals and further reduces the overall carbon emissions linked to the production process, making molded pulp an increasingly attractive choice for businesses committed to reducing their environmental impact.

Lightweight and Compact Design Reduces Transportation Emissions

One of the key molded pulp attributes is its lightweight nature. Molded pulp packaging is much lighter than traditional alternatives like glass or metal, which translates to reduced fuel consumption during transportation. Lower transportation emissions are critical in minimizing the overall carbon footprint of supply chains.

The compact design of molded pulp packaging also contributes to improved logistics efficiency. These products can be nested or stacked more effectively, enabling businesses to transport larger quantities in fewer trips. By optimizing shipping volumes and reducing the number of vehicles on the road, molded pulp packaging supports sustainable transportation practices.

Biodegradability and Compostability: Closing the Loop

Unlike materials such as plastic that can take hundreds of years to break down, molded pulp is designed to biodegrade naturally. This attribute significantly reduces the long-term environmental impact of packaging waste. Molded pulp products decompose into natural elements without releasing harmful toxins, aligning with global efforts to combat pollution and preserve ecosystems.

Compostability is another standout feature of molded pulp packaging. When disposed of in industrial composting facilities or home compost bins, these products return valuable nutrients to the soil. This regenerative process not only reduces waste but also contributes to healthier agricultural practices, creating a full-circle approach to sustainability.

Customizable and Durable for Diverse Applications

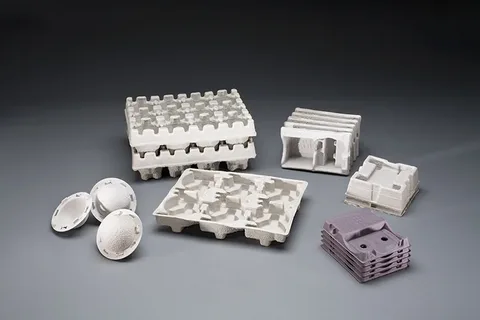

Molded pulp packaging is versatile and can be tailored to meet specific needs across various industries. Its strength and shock-absorbing properties make it an ideal choice for protecting fragile items, such as electronics or glassware, during transportation. By replacing plastic foam or bubble wrap with molded pulp, businesses can achieve comparable performance with significantly less environmental impact.

Moreover, the customizability of molded pulp allows companies to create innovative designs that enhance functionality while maintaining a commitment to sustainability. From food trays and egg cartons to protective packaging for high-tech devices, the adaptability of molded pulp ensures its relevance in reducing carbon footprints across a broad spectrum of applications.

Conclusion

The molded pulp attributes—sustainable raw materials, energy-efficient production, lightweight design, biodegradability, and customizability—position it as a game-changer in the packaging industry. As businesses and consumers alike prioritize eco-friendly solutions, molded pulp offers a viable pathway to reducing carbon footprints while meeting functional and aesthetic requirements. By adopting molded pulp packaging, companies can demonstrate their commitment to sustainability and contribute to a more resilient, environmentally conscious future.

Post Comment