How Membrane Bioreactor For Wastewater Treatment Purifies Water?

Water scarcity is becoming an increasingly important problem in the modern world, and with increasing industrialization and urbanization, there has never been a greater need for efficient wastewater treatment. One of the most advanced forms of water purification is the Membrane Bioreactor For Wastewater Treatment, or MBR. MBR represents one of the latest water treatment technologies, integrating biological processes with membrane filtration to achieve superior water treatment performance. MBR systems can remove organic and inorganic contaminants, pathogens, and suspended solids that are present in wastewater. Their design ensures the production of high-quality effluent, which can be safely reused or discharged into natural water bodies.

What is a Membrane Bioreactor?

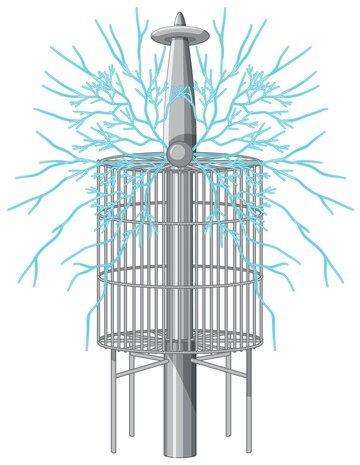

A Membrane Bioreactor For Wastewater Treatment is an integrated system that brings together biological degradation and membrane filtration in a single setup. It typically comprises two key components: a biological reactor and a membrane filtration module. The biological reactor houses microorganisms that break down organic pollutants in the wastewater, while the membrane filtration system physically separates solid particles from the treated water.

The membranes used in MBR systems are often submerged directly in the reactor, as seen with the submerged membrane modules offered by Primem. These membranes are made of hollow fibers, which act as microscopic sieves, allowing only water molecules and dissolved salts to pass through, while blocking larger contaminants such as bacteria, viruses, and suspended solids. The combination of biological and physical treatment processes makes the Membrane Bioreactor highly efficient in producing high-quality effluent.

Purification Process in MBR Systems

The water purification process in an MBR for wastewater treatment begins with the biological degradation of organic matter. Wastewater enters the bioreactor, where it is exposed to a population of microorganisms that digest organic pollutants. This biological process, known as activated sludge treatment, breaks down the complex organic matter into simpler compounds like carbon dioxide, water, and biomass.

Once the biological treatment phase is over, the mixed liquor, which carries a mixture of treated water and suspended solids such as dead microorganisms and other fine particles, passes into the membrane filtration unit. The MBR system consists of submerged membrane modules that act as a mechanical barrier. They filter out all the particles greater in size than the pores of the membrane, which ranges between 0.02 to 0.1 microns. This step ensures the removal of not only solid contaminants but also harmful pathogens, producing high-quality, pathogen-free effluent.

Role of Submerged Membrane Modules in MBR Systems

The effectiveness of a Membrane Bioreactor depends heavily on the performance of its membrane modules. Primem, a leading supplier of submerged membrane modules, offers a range of standardized and non-standardized modules tailored to meet specific treatment needs.

Its submerged membrane modules come in various configurations, including single permeate port and double permeate port models. It also comes in a variety of sizes with surface areas 10 to 35 square meters, hence useful for small-scale and large-scale water treatments. For example, the SSM10R model comes with 10 square meters of filtration area and a compact size, whereas in the DSM35H, it boasts up to 35 square meters of filtration area ideally for higher-capacity activities.

The submerged modules of reinforced or homogeneous hollow fiber membranes are, in fact, the core elements that filter the contaminants. The hollow fiber will be designed to endure the conditions prevalent in a high-pressure environment set by a MBR system for sustaining efficiency and reliability in the long run. Membrane Bioreactor For Wastewater Treatment integrates advanced membrane modules that achieve superb filtration efficiency. Indeed, it is one of the most effective methods for purifying wastewater.

Future Prospects of Membrane Bioreactor Technology

As the demand for clean water continues to grow, the Membrane Bioreactors is poised to become even more integral to modern water management strategies. The technology is evolving, with innovations such as Primem’s customizable submerged membrane modules offering new possibilities for tailored wastewater treatment solutions. These advancements are making MBR systems more accessible and affordable, expanding their use in both industrial and municipal applications.

Conclusion

The Membrane Bioreactor For Wastewater Treatment represents a significant advancement in the field of water purification. By combining biological treatment with advanced membrane filtration, MBR systems deliver high-quality effluent that meets stringent environmental standards. With the continued development of innovative membrane modules, like those offered by Primem, MBR technology is set to play a crucial role in addressing the global water crisis and ensuring a sustainable future.

Post Comment