How FRL Units Improve Compressed Air Quality and System Efficiency

Compressed air is a vital utility in industries ranging from manufacturing to pharmaceuticals. However, without proper air treatment, contaminants like dust, moisture, and oil can severely impact the performance and life span of pneumatic tools and equipment. This is where an FRL unit (Filter, Regulator, Lubricator) comes into play. Designed to condition compressed air before it reaches the end-use application, the FRL unit improves both air quality and system efficiency.

In this article, we’ll explore how FRL units function, their key benefits, and why they are essential in any pneumatic system.

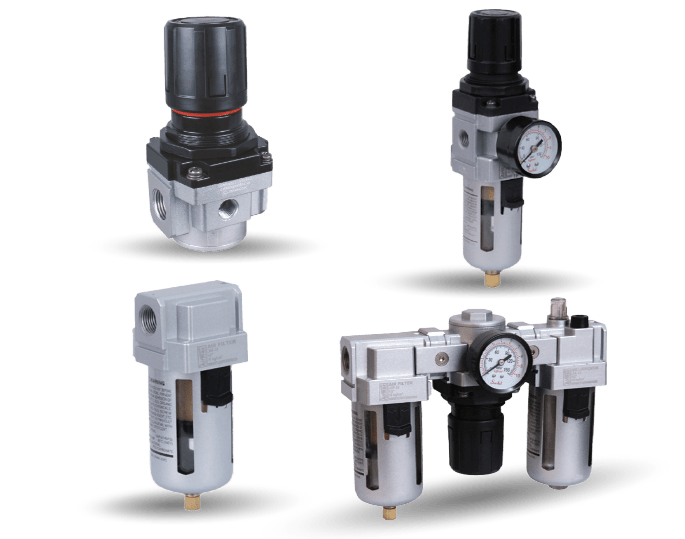

What Is an FRL Unit?

An FRL unit is a combination of three components:

- Filter (F) – Removes contaminants like dust, dirt, and moisture from compressed air.

- Regulator (R) – Controls the pressure of the air to ensure safe and consistent operation.

- Lubricator (L) – Adds a fine mist of oil to lubricate internal components of pneumatic tools and cylinders.

These three elements are often installed together as a modular or integrated assembly in pneumatic systems, positioned just before the point of use.

The Importance of Clean and Controlled Compressed Air

Compressed air is not inherently clean. It may contain water vapor, oil particles, rust, and solid contaminants, all of which can:

- Cause wear and tear on machinery

- Lead to equipment failure or breakdown

- Increase maintenance costs and downtime

- Reduce operational efficiency

The FRL unit plays a crucial role in preparing the air by filtering, regulating, and lubricating it before use. Let’s break down each component to understand how it contributes to better air quality and system efficiency.

1. Air Filter – The First Line of Defense

The air filter in an FRL unit removes water, oil aerosols, and solid particles. Clean air ensures that actuators, valves, and cylinders function without clogging or wear.

Benefits:

- Protects downstream equipment

- Prevents rust, corrosion, and abrasion

- Increases the lifespan of pneumatic tools

Modern FRL filters can remove particles as small as 5 microns, and some microfine models go down to 0.3 microns.

2. Air Regulator – Ensuring Stable Pressure

The air regulator controls the pressure of compressed air entering your equipment. Operating at the optimal pressure improves energy efficiency and prevents over-pressurization, which can damage tools and seals.

Benefits:

- Enhances control and precision

- Reduces energy consumption

- Prevents blowouts and mechanical failure

A high-quality FRL unit typically maintains pressure with minimal variation, even under load changes.

3. Lubricator – Enhancing Tool Longevity

The air lubricator injects a fine oil mist into the airflow, lubricating internal moving parts of pneumatic tools and cylinders. This reduces friction and prevents premature wear.

Benefits:

- Reduces internal corrosion and heat buildup

- Ensures smoother tool operation

- Minimizes maintenance needs

Using an FRL unit with adjustable lubrication ensures you provide just the right amount of oil—no more, no less.

How FRL Units Improve System Efficiency

Installing an FRL unit in your pneumatic system leads to measurable efficiency gains:

✅ Reduced Downtime

Clean, dry, and lubricated air reduces the frequency of equipment breakdowns.

✅ Energy Savings

Proper regulation of air pressure avoids over-pressurizing the system, which can waste energy and increase compressor load.

✅ Extended Equipment Life

By preventing contamination and reducing wear, FRL units contribute to longer-lasting tools and machinery.

✅ Better Productivity

Operators experience smoother, more predictable tool performance, which boosts overall productivity.

Applications Across Industries

FRL units are essential in:

- Automotive manufacturing – for air-powered assembly tools

- Food & beverage – ensuring hygienic compressed air

- Pharmaceuticals – for clean-room pneumatic systems

- Packaging & logistics – for actuating cylinders and conveyors

- Textile & printing – where precision air control is crucial

Wherever pneumatic systems are used, FRL units are a non-negotiable element for maintaining efficiency and air quality.

Tips for Choosing the Right FRL Unit

When selecting an FRL unit, consider:

- Port size (¼”, ½”, etc.) based on your air flow requirements

- Maximum pressure rating to match your system specs

- Material compatibility (aluminum, brass, etc.) based on the environment

- Modular vs. integrated design depending on space and flexibility needs

Make sure to inspect and replace filters and oil levels regularly for continued optimal performance.

If you want to know more about Pneumatic Cylinder

Conclusion

An FRL unit is a small but mighty component in your pneumatic system. By filtering contaminants, regulating pressure, and lubricating internal parts, it ensures high-quality compressed air that protects equipment and boosts efficiency.

Investing in a high-quality FRL unit is not just a technical decision – it’s a strategic move toward reducing operational costs, minimizing downtime, and maximizing tool performance.

Ready to upgrade your system? Choose engineered FRL units built for industrial reliability and peak performance.