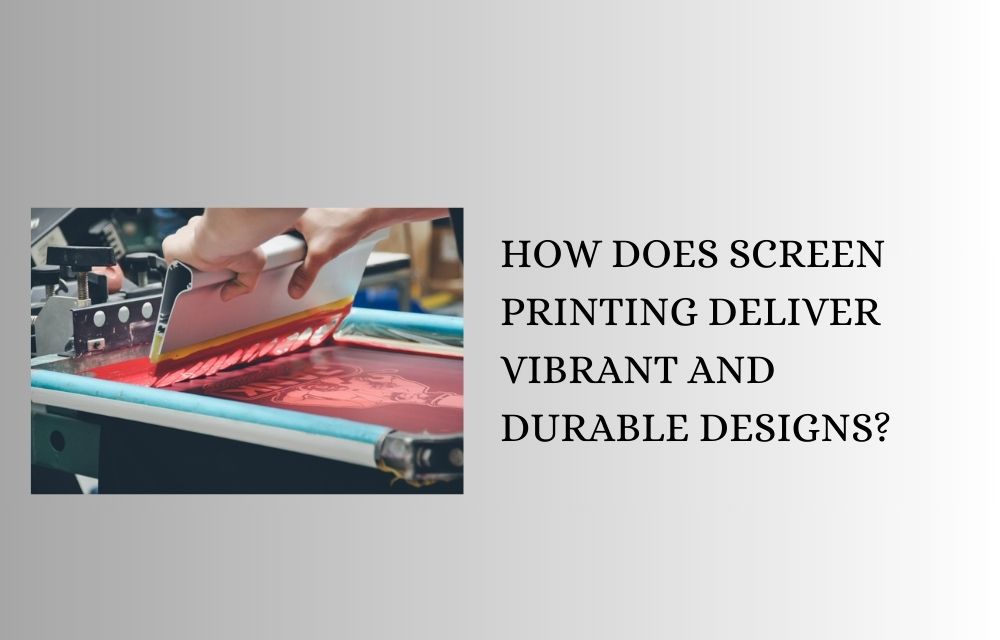

How Does Screen Printing Deliver Vibrant and Durable Designs?

Screen printing is a well-known technique that has been around for a long time, loved for its ability to create bold and long-lasting prints. From custom t-shirts to posters and other materials, screen printing is everywhere. But how does this method actually make such vibrant and durable designs? In this blog, we’ll explore the process of screen printing in a way that’s easy to understand, and we’ll break down the steps that make it such a popular printing choice.

What is Screen Printing?

Screen printing is a printing method that involves pushing ink through a screen stencil to create a design on a surface. This technique has been used for many years and is ideal for printing on fabrics, glass, wood, and even paper. The process is quite simple yet effective, which is why it remains a top choice for many people wanting to create custom designs.

Let’s take a closer look at how this process works, why it’s so vibrant and durable, and what makes screen printing stand out compared to other printing methods.

Note:- Bring your designs to life with high-quality screen printing! Al Mahrah offers professional and reliable screen printing in dubai for all your needs. Contact today to create standout prints with precision and style!

The Basics of Screen Printing

Screen printing starts with a stencil. This stencil is what makes the design, and it is placed on a screen. The screen itself is made of mesh, which allows ink to pass through it only where the design allows it. The rest of the screen is covered to block the ink.

Once the screen and stencil are ready, ink is applied to the top of the screen, and a squeegee is used to press the ink through the open areas of the stencil, transferring the design to the material below. This is why screen printing is sometimes called “serigraphy.”

The entire process may sound simple, but it requires skill and experience to get the best results. Let’s go step by step to understand why screen printing is so effective at creating bright and long-lasting designs.

Step-by-Step Process of Screen Printing

1. Creating the Design

The first step in screen printing is designing what you want to print. This can be done digitally using software like Adobe Illustrator or Photoshop. The design is then printed on a transparent film, which will be used to create the stencil.

2. Preparing the Screen

Next, the screen needs to be prepared. The screen is usually a wooden or metal frame with a fine mesh stretched across it. The mesh is then coated with a light-sensitive emulsion, which will help create the stencil.

3. Exposing the Screen

The design printed on the transparent film is placed on the screen with the emulsion. Then, it is exposed to light. The areas of the screen that are covered by the design block the light, while the rest of the emulsion hardens when exposed. After exposure, the screen is washed, and the areas that were blocked by the design wash away, leaving a stencil of the design on the mesh.

4. Applying the Ink

Now that the stencil is ready, it’s time to print. The screen is placed over the material that you want to print on, such as a t-shirt. Ink is then applied to the top of the screen and spread across the stencil using a squeegee. The ink is pushed through the open areas of the screen, creating the design on the material.

5. Curing the Design

After the ink is applied, the printed material needs to be cured. This means heating the ink to make sure it sets properly, making the design permanent. Curing can be done using a heat press or a conveyor dryer. This step is crucial because it ensures that the design won’t crack or fade easily, making it both vibrant and durable.

6. Final Inspection

Once cured, the printed material goes through a final inspection to ensure the design looks great and that the colors are vibrant. Any imperfections are corrected before the product is considered complete.

Why Does Screen Printing Create Vibrant Designs?

High-Quality Ink

One of the reasons screen printing creates such vibrant designs is the quality of ink used. Screen printing ink is much thicker compared to inks used in other printing methods, such as digital printing. This thickness allows for deeper and richer colors, which results in a more vibrant final product.

Layering Ink for Brightness

In screen printing, ink can be layered multiple times to achieve the desired brightness. Unlike other printing methods that might use a single pass of ink, screen printing can add more layers, making the colors pop. This is especially useful for designs that require bright colors on darker fabrics.

Custom Color Mixing

Another reason screen printing produces vibrant designs is the ability to mix custom colors. Screen printers often mix inks to create the exact shade needed for a particular design, which ensures the final product matches the designer’s vision perfectly.

How Does Screen Printing Ensure Durability?

Thick Ink Application

As mentioned earlier, screen printing uses thicker ink compared to other printing methods. This thick layer of ink not only makes the colors vibrant but also makes them more durable. The ink sits on top of the fabric rather than being absorbed, which helps the design withstand washing and wear over time.

Curing Process

The curing process is key to the durability of screen-printed designs. By heating the ink, it bonds properly with the material, making the print resistant to cracking, peeling, and fading. This is why screen-printed t-shirts can last for years without losing their original appeal.

High-Quality Materials

Durability also depends on the quality of the materials used. Screen printers use high-quality mesh screens and professional-grade inks that are designed to last. The combination of these materials ensures that the final product will be able to stand up to the test of time.

Advantages of Screen Printing Over Other Methods

Versatility

Screen printing is highly versatile and can be used on a wide variety of materials. Whether it’s fabric, glass, wood, or metal, screen printing can create beautiful designs on almost any surface. This versatility makes it a preferred method for many people who need custom printing.

Cost-Effectiveness for Bulk Orders

Screen printing is also cost-effective, especially for large orders. Once the screen is prepared, the actual printing process is quick and easy, which reduces the cost per item. This is why screen printing is often used for bulk orders, such as company t-shirts or event merchandise.

Long-Lasting Prints

Compared to other methods like digital printing or heat transfer, screen printing creates designs that last much longer. The curing process and the thick ink application ensure that the design won’t fade or peel, even after many washes.

Limitations of Screen Printing

Not Ideal for Small Orders

While screen printing is great for bulk orders, it’s not always the best choice for small batches. The process of preparing the screen and creating the stencil can be time-consuming, which makes it less cost-effective for printing just a few items.

Complex Designs Can Be Tricky

Screen printing is best suited for simple designs with a limited number of colors. Complex designs with multiple colors or intricate details can be challenging to produce, as each color requires its own screen, which adds to the time and cost.

Common Uses of Screen Printing

Apparel and Textiles

One of the most common uses of screen printing is on apparel, such as t-shirts, hoodies, and hats. Screen printing is ideal for creating bold, colorful designs that stand out, which is why it’s a popular choice for custom clothing.

Posters and Artwork

Screen printing is also used for creating posters and artwork. The vibrant colors and high-quality ink make it an excellent choice for artists looking to produce prints of their work.

Promotional Items

Many companies use screen printing to create promotional items like bags, pens, and other merchandise. The durability of screen-printed designs makes them perfect for items that will be used regularly.

Conclusion

Screen printing is a time-tested method that delivers vibrant and durable designs, making it a popular choice for custom printing projects. From the preparation of the screen to the curing process, every step plays a crucial role in ensuring that the final product is bright, eye-catching, and long-lasting.

Whether you’re looking to create custom t-shirts for your business, posters for an event, or promotional merchandise, screen printing offers a reliable way to bring your designs to life. Its versatility, ability to produce vibrant colors, and durability make it a top choice for both individuals and businesses alike.

If you’re considering screen printing for your next project, remember that the quality of the materials and the expertise of the printer can make all the difference. With the right approach, you can create designs that are not only visually stunning but also built to last.

Note:- For read more articles visit on freshvoicehub.

Post Comment