Energy Management and the Hidden Cost of Compressed Air Waste!

Imagine leaving your kitchen faucet running all day. You’d notice the waste—and the rising water bill. Now, apply that same logic to your compressed air system. Without real-time energy management systems monitoring, many industrial facilities are wasting compressed air the same way—silently, daily, and expensively.

Compressed air may feel “invisible,” but the costs are very real. And they’re cutting deep into your operations and sustainability goals.

The Hidden Cost of Compressed Air Mismanagement

Let’s be clear: compressed air is one of the most inefficient energy uses in any facility. It’s vital, yes—but it’s also waste-prone. Poorly managed systems often suffer from:

- Leaks that go unnoticed

- Over-pressurization to make up for inefficiencies

- Artificial demand driven by system faults

- Compressors running during idle periods

These issues aren’t just technical—they’re financial.

According to the U.S. Department of Energy, as much as 30% of compressed air in industrial systems is lost to leaks alone. That’s like throwing away one-third of your electricity spend, every day! And that doesn’t include losses due to artificial demand or inefficient pressure settings.

How Energy Management Systems Monitoring Solves the Problem

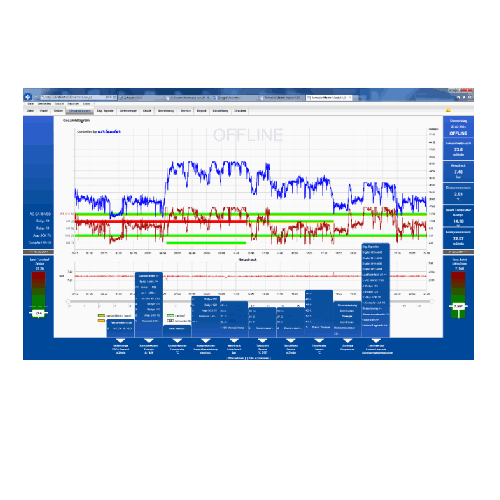

Here’s where intelligent energy management systems monitoring delivers measurable value. Modern web-based compressor management platforms aren’t just dashboards. They are smart, responsive tools that let you uncover and resolve inefficiencies in real time.

With EMS integration, you can:

- Track pressure variations across systems

- Spot usage patterns and detect waste

- Receive alerts when thresholds are crossed

- Automate compressor behavior based on demand

What does this mean for you? Real savings, smarter compliance, and full control over your air system’s energy profile.

Why Real-Time Monitoring Matters More Than Ever

You can’t manage what you can’t measure. Real-time data is now the backbone of modern energy efficiency. When your compressors are constantly monitored, anomalies don’t go unnoticed for days or weeks. You see them live, and you act immediately.

Questions to ask yourself today:

- Are your compressors frequently cycling on and off with no load?

- Is your facility using pressure setpoints higher than needed?

- Do your maintenance teams rely on reactive repair instead of preventive upkeep?

With the right compressor monitoring system, these become answerable—and solvable—questions.

Smarter Integration Leads to Greener Results

Bringing your EMS into harmony with your compressed air system isn’t just about saving energy. It’s also about supporting green certifications and compliance mandates. Here’s how integration helps:

| Integration Feature | Energy Efficiency Impact | Certification Support |

| Real-time compressor data | Adjusts operations to actual demand | LEED, ISO 50001 |

| Leak detection & repair logs | Minimizes waste and energy loss | ENERGY STAR for Industry |

| Load-sharing automation | Balances usage across compressors | Local Utility Rebate Programs |

This means every dollar saved also counts toward certifications, incentives, and public ESG goals.

Artificial Demand: The Hidden Energy Sink

Artificial demand is when your system operates at higher pressures than necessary just to overcome system faults. It’s like using a fire hose when a garden hose would do. This overcompensation inflates energy costs, stresses equipment, and hides the real issue.

Energy management systems monitoring helps you pinpoint when and where these artificial demands occur. You’ll know which zone, which process, or which time of day causes the spike—and then reduce pressure settings accordingly. Less energy, more performance.

From Reactive to Predictive Maintenance

Gone are the days when teams waited for a compressor to break down before taking action. With advanced analytics and machine learning, today’s EMS platforms do more than monitor—they predict.

Your system learns how air is used throughout the day, week, or production cycle. It adjusts accordingly. Need more flow at 10 a.m. but less at 4 p.m.? The system adapts without human intervention, reducing runtime and power draw.

That means:

- Fewer emergency repairs

- Better use of maintenance resources

- Increased system lifespan

- Lower operational risk

How to Integrate EMS With Your Existing System

Worried about the complexity? Don’t be. Most energy management systems monitoring platforms are designed for easy integration. You don’t need to rip and replace your current compressors. You simply upgrade how they’re managed. From auditing your air usage to installing sensors and controls – with minimal disruption, you can go from blind operation to intelligent control.

Time to Take Control of Your Air System

Compressed air will always be necessary. But waste? That’s optional. If you’re still guessing where your energy is going, now is the moment to change that. With smart energy management systems monitoring, you’re not just watching your compressors—you’re mastering them.

So here’s the big question:

Are you paying to waste compressed air—or investing to save it?

Let today be the day you switch from oversight to insight. Because every leak plugged, every demand optimized, and every pressure point managed is a win—for your budget, your equipment, and your sustainability mission.

Let your data do the heavy lifting. Let your system think before it runs. And let your facility lead the way in smart energy use. Power your plant. Not your waste.