How Conductive Hydrogel Nanocomposites Are Transforming Bioelectronic Applications

Conductive hydrogels represent an intriguing and rapidly advancing class of materials that have captivated researchers and industry professionals alike. Their appeal lies in their exceptional combination of biocompatibility, electrical conductivity, and mechanical resilience. These properties are not often found together in a single material, making conductive hydrogels particularly valuable and versatile for a myriad of innovative applications in the burgeoning field of bioelectronics.

The potential of conductive hydrogels stretches across numerous technological frontiers. For instance, their inherent flexibility and ability to conduct electricity seamlessly position them as ideal components for next-generation wearable electronics. These devices can easily conform to the dynamic contours of the human body, offering a level of comfort and integration unmatched by traditional rigid electronics. Imagine clothing embedded with sensors that monitor vital signs continuously or fitness trackers that provide insights with unprecedented accuracy, all made possible by the flexibility and connectivity of conductive hydrogels.

Moreover, conductive hydrogels are paving the way for breakthroughs in health monitoring and medical devices. Their biocompatibility ensures safe integration with biological tissues, which is crucial for devices that provide real-time data on physiological parameters. For example, hydrogels can be used in the development of implantable sensors that track glucose levels or cardiac activity, offering critical health information without the need for invasive procedures. These applications highlight the potential of hydrogels to revolutionize patient care by facilitating continuous, real-time monitoring of health metrics.

In the realm of robotics, conductive hydrogels are instrumental in the creation of soft robots. Unlike their rigid counterparts, soft robots constructed with hydrogel components can execute complex, delicate movements and interactions. These robots can navigate environments with precision and care, making them suitable for tasks that require a gentle touch or adaptability to varying conditions. Whether employed in minimally invasive surgery or in handling fragile archaeological specimens, soft robots enabled by conductive hydrogels showcase the versatility and capability of this remarkable material.

The advancements in conductive hydrogels are bringing us closer to a future where bioelectronics are seamlessly intertwined with our daily lives, enhancing both functionality and quality of life. Their development opens up possibilities that were once relegated to science fiction, marking significant strides in the convergence of biology and technology. As research progresses, we anticipate even greater innovations and applications, tapping into the full potential of conductive hydrogels to transform fields as diverse as healthcare, personal electronics, and robotics.

The primary advantage of conductive hydrogels lies in their ability to maintain excellent electrical conductivity while preserving superior mechanical properties. This dual capability enables a harmonious integration of biological and electronic functionalities, paving the way for novel innovations at the intersection of these fields. Key to this integration are the nanoadditives incorporated within the hydrogels, which are essential for imparting both electrical conductivity and mechanical strength to the composite matrix. These nanoadditives act as conduits for electron flow, ensuring consistent electrical performance throughout the material.

However, despite these promising attributes, the traditional methods used for preparing nanoadditives present certain limitations. Conventional techniques often lack the precision needed to control the size and uniformity of nanoassemblies. This can lead to an uneven distribution of composite materials and a lack of control over microstructure at the submicron scale. The resultant poor dispersion of nanoadditives within the polymer matrix often leads to compromised properties, undermining the potential benefits of the hydrogels’ conductive and mechanical prowess.

To address these challenges, researchers have been keenly exploring bottom-up approaches for the precise assembly of uniform nanostructures. This innovative strategy allows for the meticulous construction of nanocomposites at the molecular level. By doing so, scientists can more accurately explore the structure-activity relationships inherent in these composites, paving the way for the development of nanocomposites with tailor-made properties and enhanced performance characteristics.

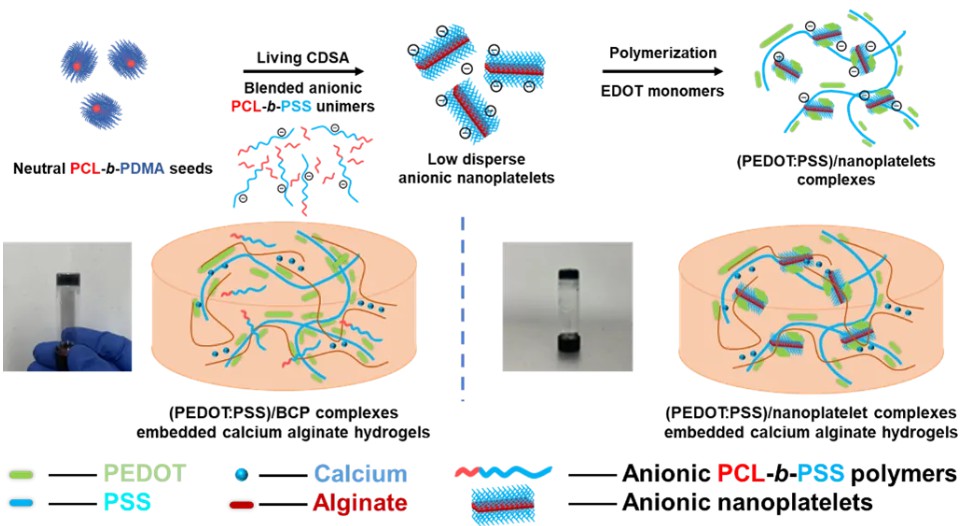

In a groundbreaking advancement, researchers have introduced an innovative methodology to prepare nanocomposite hydrogels that exhibit both exceptional mechanical properties and enhanced electrical conductivity. The approach begins with the preassembly of polycaprolactone block copolymer nanosheets with a uniform size configuration. These polyanionic nanosheets are integrated as fillers, playing a pivotal role in bolstering both the conductivity and mechanical integrity of the composite materials. Specifically, the addition of these nanosheets significantly enhances the performance of poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS)/nanosheet conductive hydrogels.

The process starts with the synthesis of PCL-b-PSS diblock copolymers that are abundant in sulfonic acid groups. Through a meticulously controlled crystallization-driven self-assembly method, these block copolymers form into uniform two-dimensional polyanionic nanosheets. The configuration ensures that the PSS block resides on the nanosheet’s surface, promoting solvent affinity and facilitating further reactions. These negatively charged nanosheets, acting as counteranions, actively participate in the polymerization of 3,4-ethylenedioxythiophene. This leads to the production of PEDOT:PSS/nanosheet composite organic semiconductors, showcasing an impressive improvement in electrical conductivity.

Further, by mixing the PEDOT:PSS/nanosheet complex with alginate, researchers successfully fabricated nanocomposite calcium alginate conductive hydrogels. These hydrogels demonstrated remarkable mechanical properties, notably superior shear resistance compared to previous iterations. The study thus highlights that a bottom-up assembly approach in the creation of nanocomposite hydrogels not only advances mechanical and electrical properties but also provides a framework for understanding structure-activity dynamics in nanocomposites, enabling the crafting of materials with precise, controllable attributes.