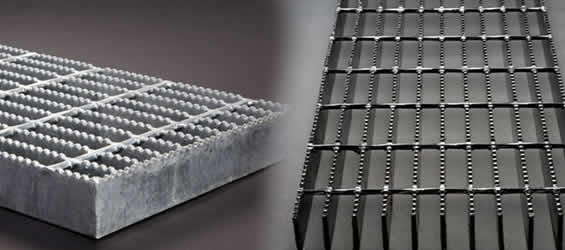

Metal Gratings: An In-Depth Guide

Metal gratings are essential in various industrial and architectural applications. These versatile materials provide support, ensure safety, and add aesthetic value to structures. In this blog, we will explore the types of metal gratings, their applications, benefits, and why stainless steel gratings stand out as a preferred choice.

Types of Metal Gratings

Metal gratings come in different materials and designs, each suited for specific purposes. Here are the most common types:

1. Stainless Steel Gratings

Stainless steel gratings are known for their durability, resistance to corrosion, and high strength. They are often used in environments where moisture and chemicals are present, such as in chemical plants, food processing facilities, and offshore platforms.

2. Carbon Steel Gratings

Carbon steel gratings are cost-effective and provide excellent strength. They are commonly used in industrial settings for walkways, platforms, and stair treads. However, they require a protective coating to prevent rust and corrosion.

3. Aluminum Gratings

Aluminum gratings are lightweight and resistant to corrosion, making them suitable for applications where weight is a concern, such as in marine environments and transportation industries.

4. Fiberglass Gratings

Fiberglass gratings are non-conductive, lightweight, and corrosion-resistant. They are ideal for environments where electrical conductivity needs to be minimized, such as in power plants and chemical industries.

Applications of Metal Gratings

Metal gratings are used across various industries due to their strength and versatility. Some of the common applications include:

1. Industrial Flooring

Metal gratings provide a strong and durable flooring option for factories and warehouses, ensuring safety and support for heavy machinery and equipment.

2. Stair Treads and Walkways

Gratings are used in the construction of stair treads and walkways, offering slip resistance and durability in both indoor and outdoor settings.

3. Drain Covers and Ventilation Grates

Metal gratings serve as effective drain covers and ventilation grates, allowing fluids and air to pass through while providing a sturdy surface.

4. Security Fencing

Due to their robust nature, metal gratings are also used in security fencing, offering protection without compromising visibility.

Benefits of Stainless Steel Gratings

Stainless steel grating are particularly favored for several reasons:

1. Corrosion Resistance

Stainless steel gratings resist rust and corrosion, even in harsh environments. This makes them ideal for use in marine and industrial applications where exposure to moisture and chemicals is common.

2. Strength and Durability

The high tensile strength of stainless steel gratings ensures they can support heavy loads without bending or breaking. This durability extends their lifespan, making them a cost-effective solution in the long run.

3. Aesthetic Appeal

Stainless steel gratings have a sleek and modern appearance, making them suitable for architectural applications where aesthetics are as important as functionality.

4. Low Maintenance

The ease of cleaning and maintaining stainless steel gratings reduces the need for frequent replacements or repairs, saving both time and money.

Applications of Metal Gratings

The versatility of metal gratings allows them to be used in a variety of applications, including:

1. Industrial Flooring

Metal gratings provide robust flooring solutions in industrial settings, capable of supporting heavy machinery and foot traffic.

2. Walkways and Platforms

Used extensively in constructing walkways and platforms, metal gratings offer a safe, slip-resistant surface in both indoor and outdoor environments.

3. Drain Covers and Ventilation Grates

Gratings are used as drain covers and ventilation grates, allowing fluid and air passage while maintaining a solid, safe surface.

4. Security Enclosures

Due to their strength and durability, metal gratings are used in security enclosures and fencing, providing protection without obstructing visibility.

Why Choose Stainless Steel Metal Grating?

When selecting metal gratings for a project, stainless steel gratings offer unmatched advantages. Their ability to withstand extreme conditions, combined with their aesthetic appeal, makes them a versatile choice for both industrial and architectural applications. Whether it’s for a factory floor or a decorative facade, stainless steel gratings provide a reliable and attractive solution.

Conclusion

Metal gratings play a crucial role in various industries by offering strength, durability, and safety. Among the different types, stainless steel gratings stand out for their corrosion resistance, strength, and aesthetic appeal. Choosing the right type of metal grating for your project ensures long-lasting performance and value.

Post Comment