How Cloud Computing is Transforming Manufacturing IT Services

The manufacturing industry has been undergoing profound transformations driven by advancements in digital technologies. One of the most impactful innovations reshaping manufacturing IT services is cloud computing. As companies strive to stay competitive, cloud-based IT infrastructure offers new ways to streamline operations, reduce costs, and enhance productivity. This article explores how cloud computing is transforming manufacturing IT services and how it aligns with Industry 5.0 to meet future demands.

1. The Role of Cloud Computing in Manufacturing IT Services

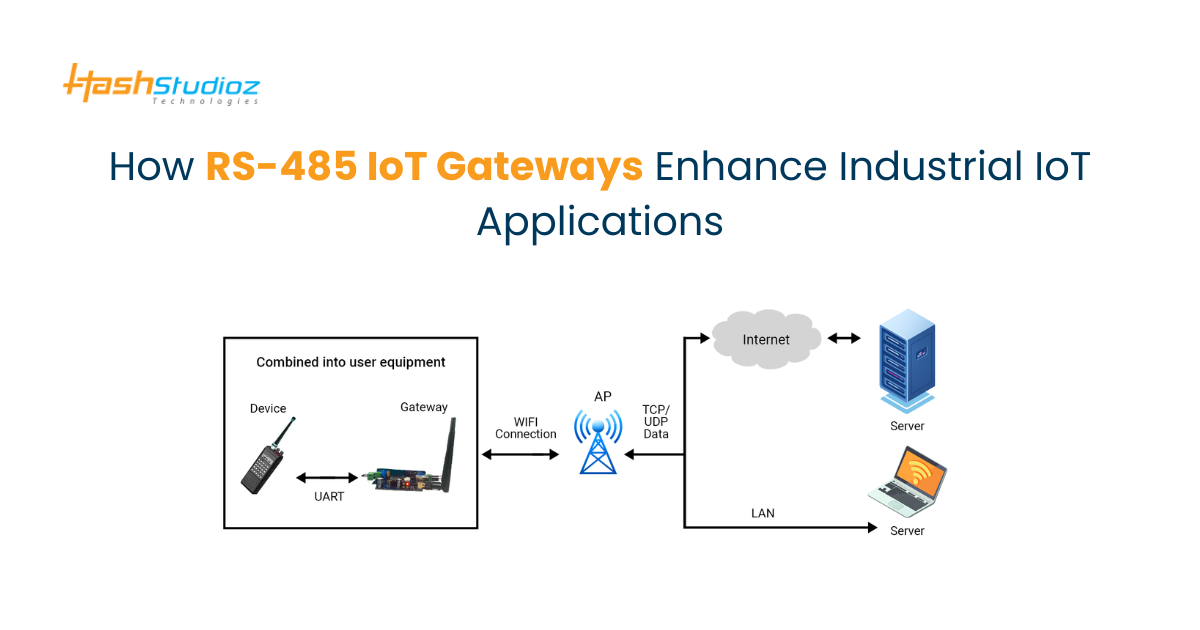

Cloud computing refers to the delivery of computing services—such as servers, storage, databases, networking, and software—over the internet. In the manufacturing sector, cloud-based solutions enable organizations to manage operations more efficiently by hosting software and data on remote servers. Unlike traditional on-premise systems, cloud-based services offer greater flexibility, scalability, and security.

IT services for manufacturing are evolving as companies adopt cloud platforms to drive digital transformation. From managing production lines to enhancing supply chain operations, cloud computing provides a central hub for real-time monitoring, data analytics, and automated processes.

2. Key Ways Cloud Computing Transforms Manufacturing IT Services

2.1. Enhanced Data Management and Analytics

The manufacturing process generates vast amounts of data from multiple sources, such as sensors, machines, and production lines. Cloud computing enables companies to store and analyze this data in real-time through centralized cloud databases.

With powerful analytical tools hosted on cloud platforms, manufacturers can identify bottlenecks, forecast maintenance requirements, and optimize production schedules. Big data analytics allows companies to derive actionable insights that drive decision-making and improve overall efficiency.

Example: Predictive maintenance solutions hosted in the cloud can analyze historical data to forecast when a machine will require repairs, reducing downtime and repair costs.

2.2. Greater Scalability and Flexibility

Cloud platforms provide scalable infrastructure that can adjust to meet the changing needs of manufacturers. Companies no longer need to invest heavily in physical servers to meet peak demand; instead, they can scale up or down their computing resources based on real-time production requirements.

This flexibility makes it easier for manufacturers to adapt to market fluctuations, respond quickly to customer demands, and launch new products. Moreover, manufacturers expanding to new locations can deploy cloud-based IT services without setting up extensive on-site infrastructure.

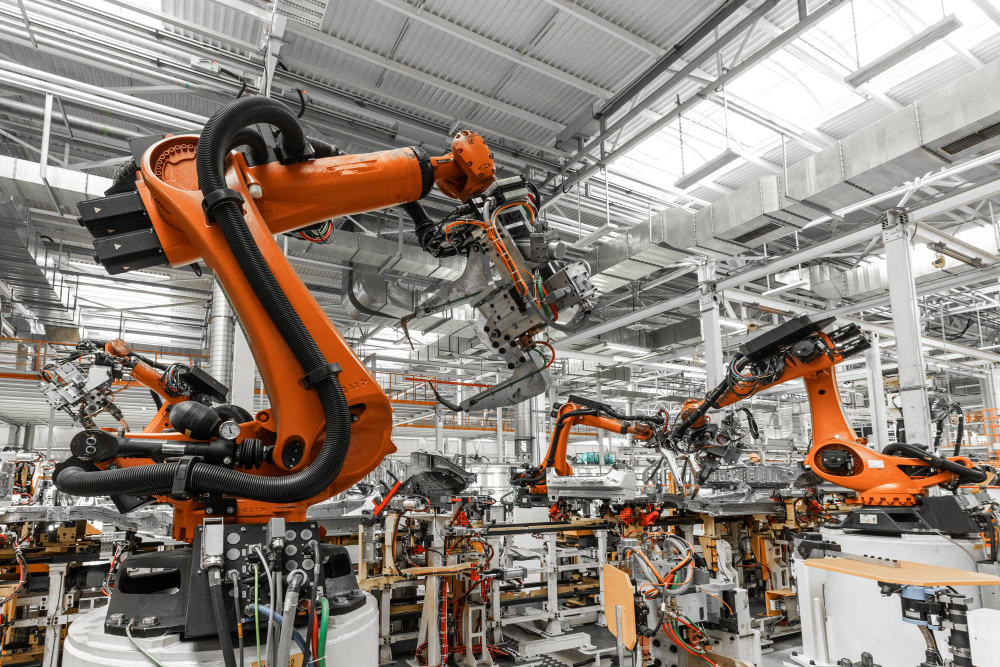

2.3. Facilitating Industry 4.0 and Enabling Industry 5.0

Cloud computing is a critical enabler of both Industry 4.0 and Industry 5.0. While Industry 4.0 emphasizes automation, IoT, and smart factories, Industry 5.0 in manufacturing focuses on human-machine collaboration, sustainability, and personalized production. Cloud platforms provide the foundation for this transition by connecting robots, AI systems, and human operators seamlessly.

In Industry 5.0, workers and machines collaborate in real time to create highly customized products with minimal waste. Cloud-based IT services facilitate this collaboration by ensuring smooth data exchange between intelligent machines and human interfaces.

2.4. Improved Supply Chain Visibility

Supply chain disruptions are common in modern manufacturing. Cloud computing provides manufacturers with end-to-end visibility into their supply chain operations by integrating suppliers, logistics partners, and production units through a unified platform.

With cloud-based IT services, companies can monitor inventory levels, track shipments, and coordinate with suppliers in real time. This ensures that production schedules remain unaffected by unforeseen delays and helps reduce costs associated with excess inventory or stockouts.

Example: A cloud-based ERP system allows manufacturing plants to access real-time supplier information and quickly adjust production schedules based on material availability.

2.5. Cost Efficiency and Lower IT Maintenance

Maintaining on-premise infrastructure can be costly, requiring regular updates, hardware replacements, and dedicated IT personnel. Cloud computing reduces these overhead costs by outsourcing data storage, software maintenance, and system upgrades to cloud service providers.

With cloud-based IT services, manufacturing companies only pay for the resources they use, helping them manage budgets more effectively. Additionally, cloud providers offer automatic updates, ensuring that companies always have access to the latest technologies without downtime.

3. The Role of Cloud Computing in Supporting Sustainability

Sustainability has become a core focus for many manufacturers, and cloud computing plays a vital role in reducing the industry’s environmental impact. Cloud platforms promote more sustainable operations by enabling remote monitoring, predictive maintenance, and waste reduction.

By optimizing production processes through cloud analytics, manufacturers can reduce energy consumption and minimize material waste. Furthermore, cloud computing allows for remote work and collaboration, which decreases the need for travel and reduces the carbon footprint associated with business operations.

4. Security and Compliance in Cloud-Based Manufacturing IT Services

While cloud computing offers many advantages, it also introduces security challenges that must be addressed. Manufacturing companies often deal with sensitive data, including intellectual property, customer information, and production secrets. To ensure data security, manufacturers must work with cloud providers that offer robust encryption, firewalls, and access controls.

Compliance with industry regulations is also critical. Cloud-based IT services for manufacturing must align with regulatory standards such as ISO 27001, GDPR, or industry-specific guidelines to avoid legal complications.

5. Real-World Applications of Cloud Computing in Manufacturing

Several manufacturers are already leveraging cloud computing to enhance operations:

- Siemens: The company uses cloud-based platforms for remote monitoring of industrial equipment, improving efficiency through predictive analytics.

- Tesla: Cloud services help Tesla manage production data and software updates remotely across its global factories.

- GE Aviation: Cloud platforms enable real-time data sharing between GE Aviation and its customers, facilitating predictive maintenance and reducing aircraft downtime.

These examples demonstrate the power of cloud-based IT services in creating agile, efficient, and customer-focused manufacturing operations.

6. Challenges of Adopting Cloud Computing in Manufacturing

While cloud computing offers numerous benefits, manufacturers must overcome certain challenges:

- Integration Issues: Migrating legacy systems to the cloud can be complex and time-consuming.

- Data Security Concerns: Ensuring the safety of sensitive manufacturing data requires robust security frameworks.

- Employee Training: Workers must be trained to operate cloud-based systems efficiently and adapt to new workflows.

Despite these challenges, the benefits of cloud computing far outweigh the obstacles, making it a vital component of modern manufacturing IT services.

Conclusion

Cloud computing is revolutionizing IT services for manufacturing, offering new ways to optimize operations, enhance collaboration, and drive innovation. As the industry moves toward Industry 5.0, cloud platforms will play an even greater role in enabling human-machine collaboration and sustainable production.

Manufacturers embracing cloud computing can achieve greater efficiency, flexibility, and cost savings while staying ahead of industry trends. By overcoming initial challenges and leveraging cloud-based IT services, companies can unlock new opportunities and remain competitive in a rapidly evolving market.

Post Comment